15.1

1 × 10-8 mbar to 1 bar (abs)

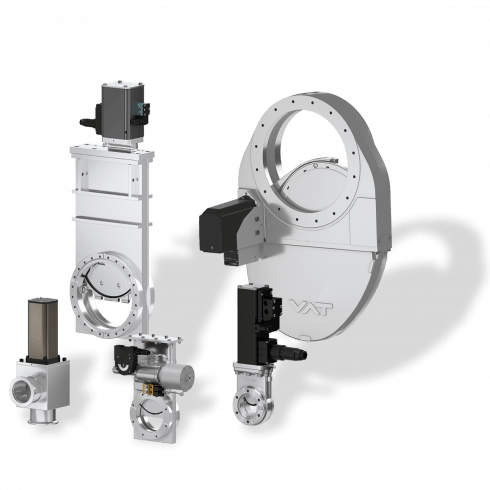

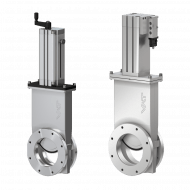

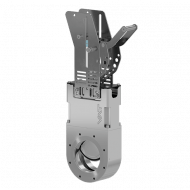

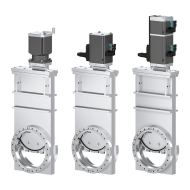

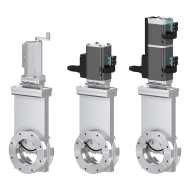

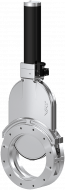

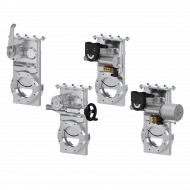

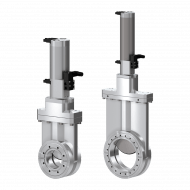

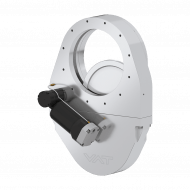

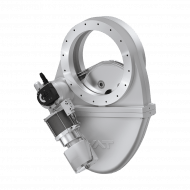

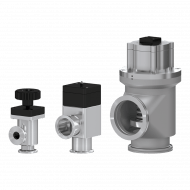

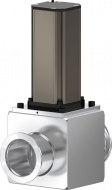

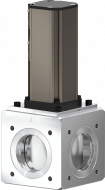

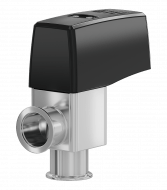

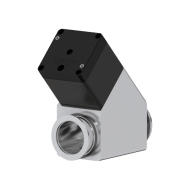

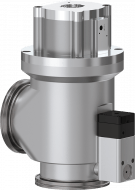

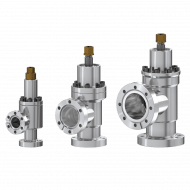

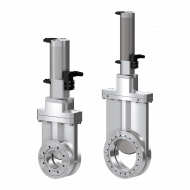

HV Isolation Gate Valve

Exceptionally Low Shock and Particle Count

FAQ Vacuum Isolation Valves

What are vacuum isolation valves?

A vacuum isolation valve is a type of vacuum valve designed to isolate a section of a vacuum system from the rest of the system. The purpose of the valve is to prevent gas or air from entering or leaving the isolated section, thereby maintaining the vacuum level in that section.

How does a vacuum isolation valve work?

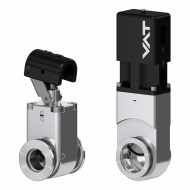

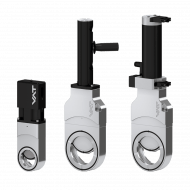

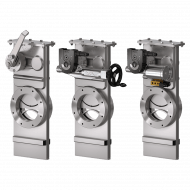

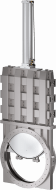

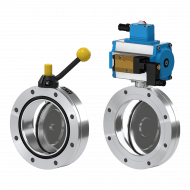

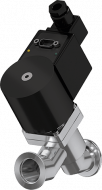

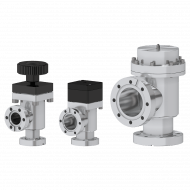

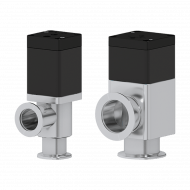

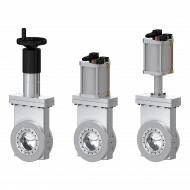

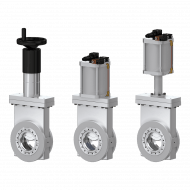

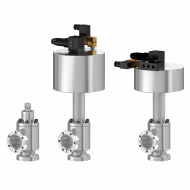

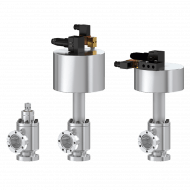

Vacuum isolation valves work by using a mechanism to physically block the flow of gas or air. In contrast to vacuum valves, which have a pure gas flow regulating function, for example. This mechanism can vary according to the application. The isolation is achieved by either pushing, rotating or swinging a gate into the flow path. A key characteristic of high performance vacuum isolation valves is to do this with nearly no vibration or friction even at very fast opening and closing speeds. A vacuum isolation valve is typically made of aluminum or stainless steel with an elastomer sealing. To withstand harsh operation conditions like high temperatures, radiation or aggressive media isolation valves can also be made fully of metall. Also in ultra high and extreme high vacuum applications all-metal isolation valves with hard-on-hard sealing are preferred as elastomer sealing as they provide better sealing performance and durability.

What are some common applications for vacuum isolation valves?

Vacuum isolation valves are used in a wide range of applications, including semiconductor manufacturing, vacuum coating, research and development, and many other industries that require a controlled vacuum environment.

What are some important factors to consider when selecting a vacuum isolation valve?

When selecting a vacuum isolation valve, it's important to consider factors such as the material of the vacuum valve body and sealing mechanism, the valve size and flow rate, the required level of vacuum, and any special requirements for the application.

How can I maintain and troubleshoot a vacuum isolation valve?

To maintain and troubleshoot a vacuum isolation valve, it's important to follow the manufacturer's instructions and guidelines. Regular maintenance can help to prevent issues such as leaks or blockages, and troubleshooting may involve checking for wear and tear on the vacuum valve components, cleaning or replacing parts as needed, and performing tests to ensure proper valve function. If in doubt, consult a vacuum system expert for assistance.