Solar Thin Film Deposition

Solar panel manufacturers use a variety of coating processes (CVD, ALD, MBE, PVD, etc.) to produce the ultra-thin films that make up the performance o...

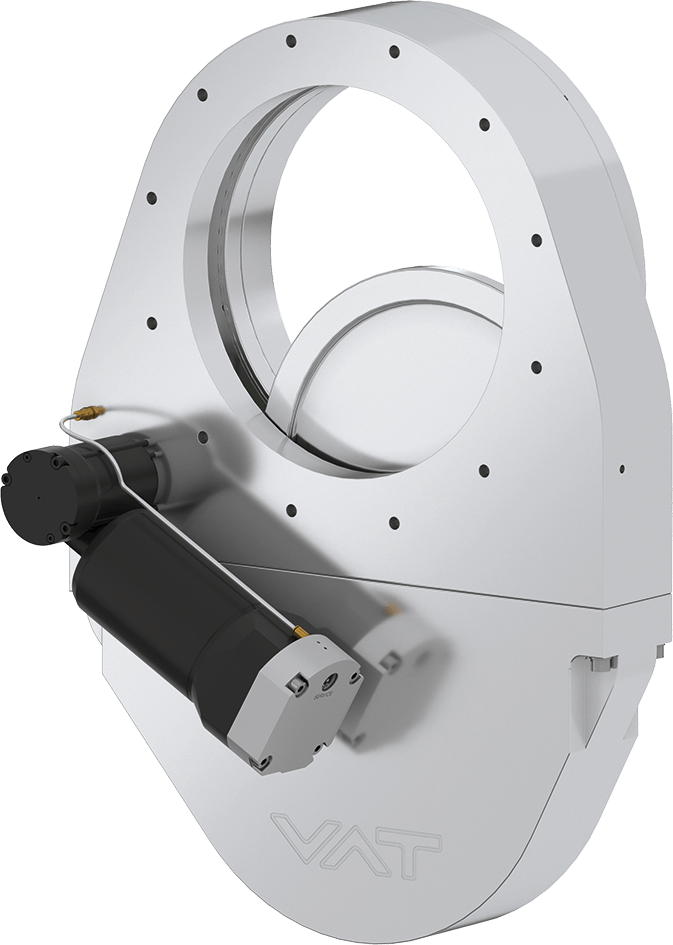

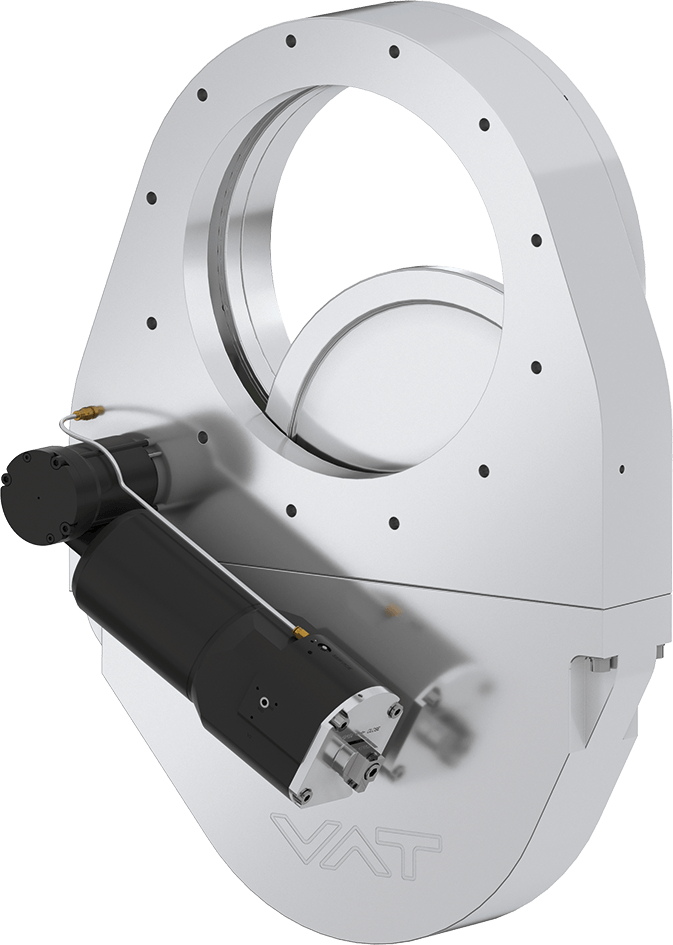

Read moreThe 16.2 HV Pendulum Isolation Valve provides reliable isolation performance combined with low particle count and low particle activation. The excellent particle performance is achieved by an exceptionally smooth opening and closing motion.

It is ideal for isolation requirements in harsh processes such as in evaporator and sputter applications. The 16.2 valve provides a 3-position pneumatic, single acting with closing spring or a standard pneumatic, single acting with closing spring.

With its special split body design it allows maintenance without any disassembly of pipe connections or process chamber connections. Its slim design allows to mount the 16.2 directly to a process chamber, eliminating e.g. the volume normally required in a chamber - valve - pump connection.

With its robust design as well as a variety of design options, the 16.2 series is easy to integrate into various vacuum processes.

Already installed in hundreds of batch and inline production systems around the world under various process conditions, the 16.2 series has proven its outstanding performance in all aspects.

The 16.2 HV Pendulum Isolation Valve is available in aluminum, the body hard anodized or nickel-plated with standard flange connectors in ISO-F, ASA-LP and JIS. Customer-specific flanges can be integrated. Further options are ports for roughing (by-pass), venting or for gauges, heating solution as well as a window in the plate with borosilicate or sapphire glass.

Features:

Benefits:

| Sizes | DN 200 (8"), DN 250 (10"), DN 320 (12"), DN 350 (14"), DN 400 (16"), DN 500 (20") |

|

|---|---|---|

| Actuators | Pneumatic | Single acting with closing spring (NC) |

| 3-Position Pneuatic | Single acting with closing spring (NC) | |

| Body Material | Aluminum | |

| Feedthrough | Rotary feedthrough | |

| Standard Flanges | ISO-F, ASA-LP, JIS | |

| Leak Rate | Valve body, valve seat | < 1 × 10-8 mbar ls-1 |

| Pressure range | 1 × 10-8 mbar to 1.2 bar (abs) | |

| Differential pressure on the plate | ≤ 1.2 bar | |

| Differential pressure at opening | DN 200 DN 250 - 500 |

≤ 10 mbar ≤ 5 mbar |

| Cycles until first service | 200 000 | |

| Temperature | Valve body Actuator Solenoid valve Position indicator |

≤ 120 °C ≤ 80 °C ≤ 50 °C ≤ 80 °C |

| Heating and cooling rate | ≤ 30 °C h-1 | |

| Material | Valve body, plate, sealing ring DN 200-400 DN 500 Feedtrough (parts in contact with media) |

EN AW-5083 (3.3547), EN AW-6082 (3.2315) EN AC-42100 (3.2371) AISI 303 (1.4305), AISI 304 (1.4301) |

| Seal | Bonnet, plate, dynamic, feedthrough | FKM (Viton®) |

| Mounting position | Any | |

| Solenoid valve | 24 V DC, 5.4 W (others on request) | |

| Position indicator | Voltage Current |

≤ 50 V AC/DC ≤ 1.2 A |

| Valve position indication | Visual (mechanical) |