Sputtering

PVD sputtering is a core process in display production. An important manufacturing step is, for example, backplane metallization, in which conductive...

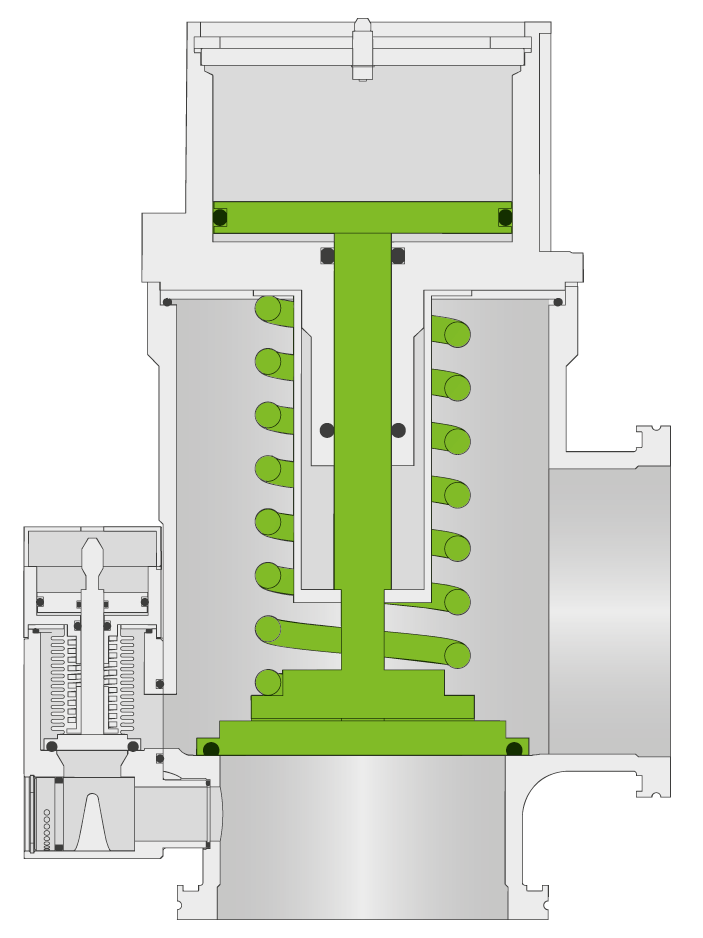

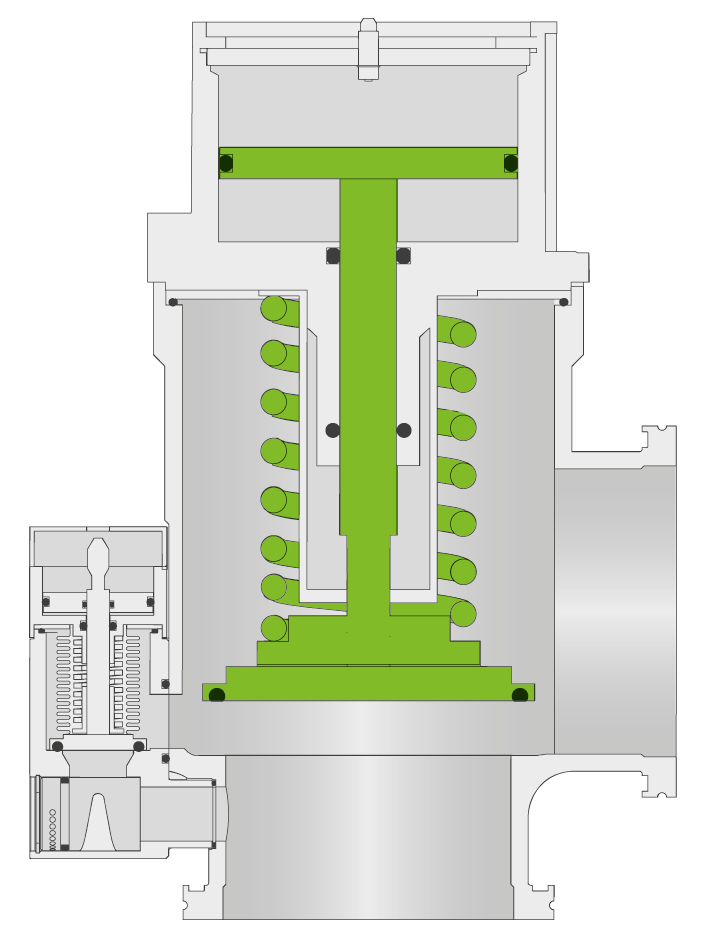

Read moreThe main requirement for a valve with a soft-pump function is to avoid turbulence The main requirement for a valve with a soft-pump function is to avoid turbulence when the valve opens, as this could have a negative impact when pumping down the load lock (LL) chamber by the swirling of particles. In addition, rapid pressure changes due to a high differential pressure when the valve opens could cause sudden condensation effects, which could also adversely affect process parameters.

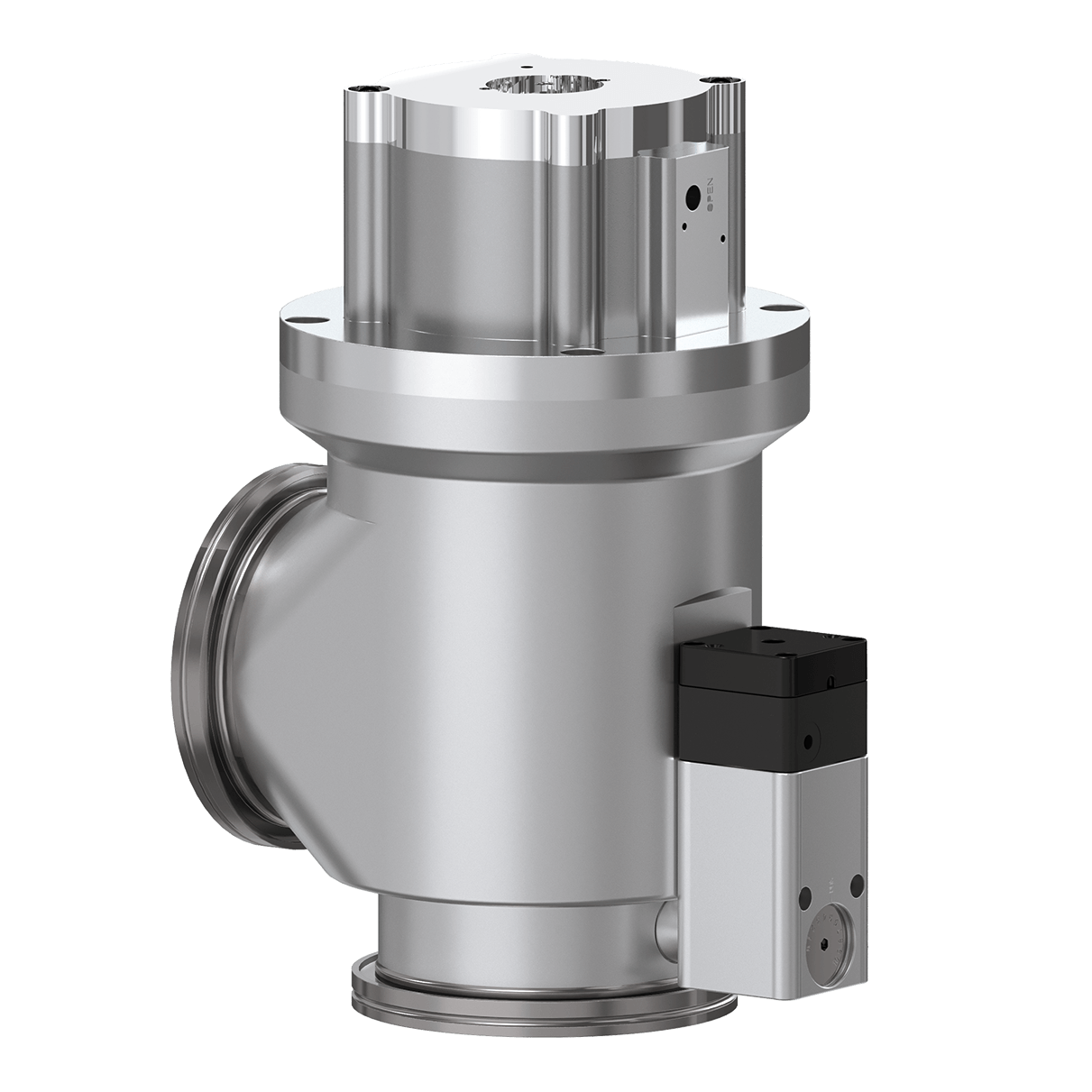

The 29.2 HV angle valve with soft-pump function avoids this.

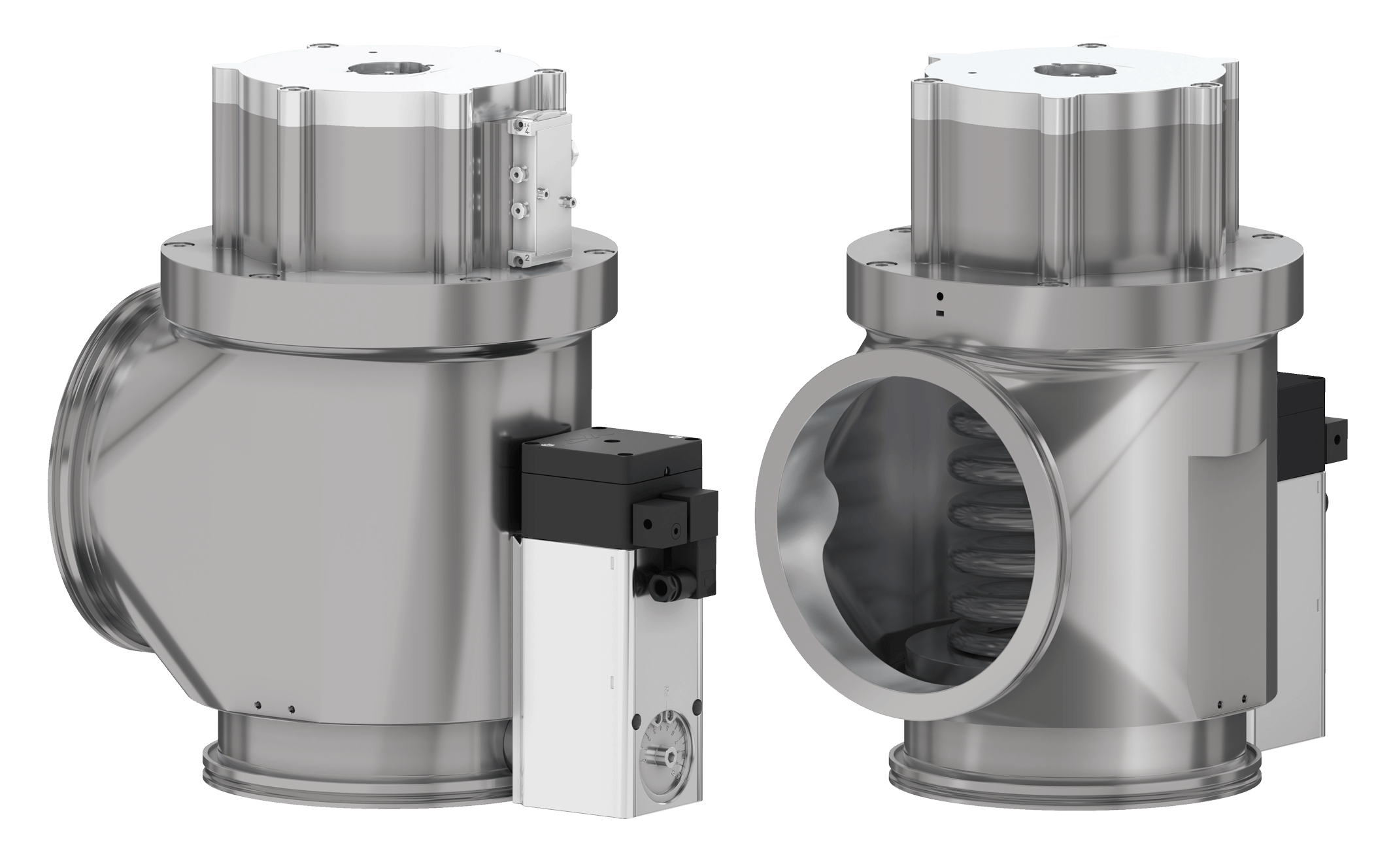

The soft-pump function of the 29.2 makes it particularly suitable for large volume flows that need to be precisely calibrated over a large possible conductance spectrum. The large conductance spectrum is achieved by combining two high vacuum angle valves, where the main valve interacts with a bypass valve in one compact assembly.

An adjustment wheel on the side of the valve allows fine-tuning of the soft-pump effect. This allows optimum calibration to the desired process parameters over a very wide conductivity spectrum.

To enable simple and precise adjustment as well as easy resetting, the wheel is provided with 11 position markings. These facilitate the reproducibility of a setting as well as copying the setting to other valves that are to operate with the same setting.

In this design, the 29.2 is outstanding for its performance spectrum in terms of precision and compact construction. What in other configurations can only be achieved with multiple valves and additional piping, the 29.2 offers in a single solution.

For temperature-sensitive processes that are prone to condensation, the 29.2 can be equipped with an integrated PTC heater.

Especially in demanding applications with large load lock chamber volumes under changing pressure conditions, such as solar cell or display manufacturing, the 29.2 series has proven its excellent “soft” operation.

A positive side effect of the dual soft-pump function is that any impulse noise is reduced or eliminated. This results in a quieter production/operating environment.

The 29.2 HV angle valve with soft-pump function is based on a reliable and robust core construction designed for long maintenance-free operation. Should maintenance be necessary, it can be done easily and quickly.

Different combinations of main and bypass valve are available for the 29.2: DN 100 mm with DN 25 mm bypass and DN 160 mm with DN 25, DN 40 or DN 63 mm bypass. There are also two pneumatic actuator options: single acting with closing spring (NC) and double acting. The 29.2 is available in aluminum or stainless steel design.

Standard flange connection options include ISO-KF and ISO-K, but custom flanges can be incorporated. A visual position indicator and an electrical position output signal are standard.

| Sizes |

DN 100 (4"), DN 160 (6") |

||

|---|---|---|---|

| Actuator | Pneumatic | Main Valve Double acting, Soft-Pump Valve Single acting with closing spring (NC) | |

| Body Material | Aluminum or Stainless Steel | ||

| Feedthrough | Shaft Feedthrough | ||

| Standard Flanges | ISO-KF, ISO-K | ||

| Leak Rate | Valve Body | < 1 × 10-9 mbar ls-1 | |

| Valve Seat | < 1 × 10-9 mbar ls-1 | ||

| Pressure Range | 1 × 10-7 mbar to 2 bar (abs) | ||

| Differential Pressure on the Plate | In Opening Direction | ≤ 1.2 bar | |

| In Closing Direction | ≤ 2.0 bar | ||

| Differential Pressure at Opening | ≤ 1 bar | ||

| Temperatur | Valve Body | ≤ 150 °C | |

| Actuator | ≤ 80 °C | ||

| Solenoid Valve | ≤ 80 °C | ||

| Position Indicator | ≤ 80 °C | ||

| Material | Main Valve Body: Aluminum | EN AC-42000 | |

| Main Valve Body: Stainless Steel | AISI 304 (1.4301) , AISI 316L (1.4404) | ||

| Soft-Pump Valve Body | EN AW-6060 (3.3206), EN AW-6061 (3.3211), EN AW-6063 (3.3206), EN AW-6082 (3.2315) |

||

| Plate | AISI 316L (1.4404, 1.4435) or AISI 304L (1.4306) | ||

| Bellows | AISI 316L (1.4404, 1.4435), AISI 316Ti (1.4571) | ||

| Seal | Bonnet, Plate | FKM (Viton®) | |

| Mounting Position | Any | ||

| Solenoid Valve | 24 VDC, 9.0 W (others on request) | ||

| Position Indicator: Contact Rating | Voltage | 5 – 50 VAC/DC | |

| Current | 5 – 100 mA | ||

| Valve Position Indication | Visual (Mechanical) | ||