Electron Microscopy, Metrology, Inspection & Defect Review

The control of the vacuum environment used in the field of electron microscopy, metrology, inspection & defect review requires high-precision vacuum v...

Read moreThe 14.0 HV Gate Valve series is designed for reliable isolation in standard high cycle vacuum processes. It addresses the standard requirements of durability, modularity and serviceability with a special focus on high uptime and low cost of ownership.

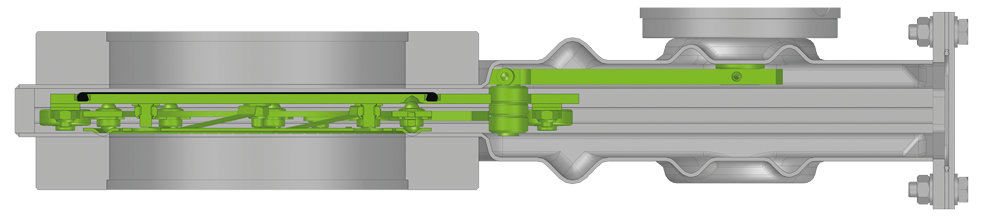

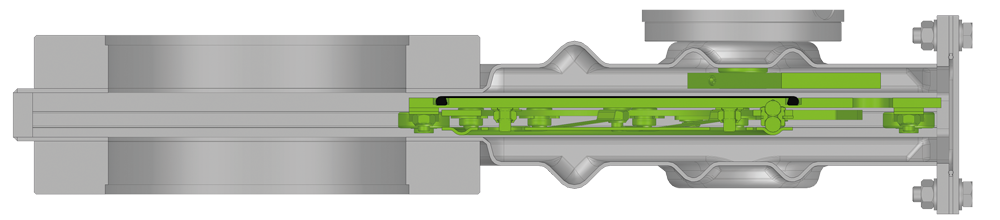

The 14.0 HV Gate Valve is equipped with VATLOCK technology which is specially developed to provide reliable sealing without any friction at the gate seal. The VATLOCK mechanism also prevents valve failures thanks to the mechanical lock-in at the closed end position.

Already installed in thousands of demanding applications under various process conditions, the 14.0 has proven its outstanding reliability. It has become the standard for any high vacuum isolation requirement in sizes from DN 63 – 400mm (2.5" – 16").

With its robust and lubricant-free design, it meets all of the requirements for a reliable HV Gate Valve. Designed for an especially high number of process cycles, the 14.0 really does set the standard.

The 14.0 has various actuation and flange connection design options so it can be easily integrated into any vacuum system. A wide range of special options are available such as ports for roughing, venting or gauges, as well as alternative sealing materials to ensure optimal fit for different applications.

The 14.0 HV Gate Valve is available as manual, pneumatic and 3-position pneumatic versions with solenoid valves, either as an on-board solution or for external mounting. The solenoid valve’s standard voltage is 24 VDC but other voltages are available upon request.

The standard options for flanges connectors are ISO-F, CF-F, ASA-LP/ASA and JIS. Customer specific flanges with and without water-cooling can be integrated.

Features:

Benefits:

| Sizes | DN 63 (2½’’), DN 80 (3"), DN 100 (4"), DN 160 (6"), DN 200 (8"), DN 250 (10"), DN 320 (12"), DN 400 (16") | ||

|---|---|---|---|

| Actuator | 3-Position-Pneumatic | Double acting | |

| Manual | With lever or handwheel | ||

| Body Material | Stainless Steel | ||

| Feedthrough | Rotary Feedthrough | ||

| Standard Flanges | ISO-F, CF-F, ASA-LP/ASA, JIS | ||

| Leak Rate | Valve Body | < 1 × 10-9 mbar ls-1 | |

| Valve Seat | < 1 10-9 mbar ls-1 | ||

| Pressure Range | 1 × 10-8 mbar to 2 bar (abs) (DN 63 – 200) 1 × 10-8 mbar to 1.2 bar (abs) (DN 250 – 400) |

||

| Differential Pressure | On the Gate | ≤ 2 bar (DN 63 – 200) ≤ 1.2 bar (DN 250 – 400) |

|

| At Opening | ≤ 30 mbar | ||

| Cycles until first Service | 200 000 | ||

| Temperature | Valve Body | ≤ 150 °C | |

| Pneumatic Actuator | ≤ 50 °C | ||

| Manual Actuator | ≤ 80 °C | ||

| Solenoid Valve | ≤ 50 °C | ||

| Position Indicator | ≤ 80 °C | ||

| Heating and Cooling Rate | ≤ 50 °C h-1 | ||

| Material | Valve Body | AISI 304 (1.4301) | |

| Mechanism | AISI 301 (1.4310), AISI 304 (1.4301) AISI 316L (1.4404), AISI 420 (1.4034) |

||

| Seal | Bonnet, Gate | FKM (Viton®) | |

| Mounting Position | Any (DN 63 – 350) Horizontal (DN 400) |

||

| Solenoid Valve | 24 VDC, 2.5 W (others on request) | ||

| Position Indicator: Contact Rating | Voltage | ≤ 250 VAC | ≤ 50 VDC |

| Current | ≤ 5 A | ≤ 3 A | |

| Valve Position Indication | Visual (Mechanical) | ||