Proton Therapy

Proton therapy as a medical treatment process is implemented in different technical concepts, with different requirements for the vacuum systems invol...

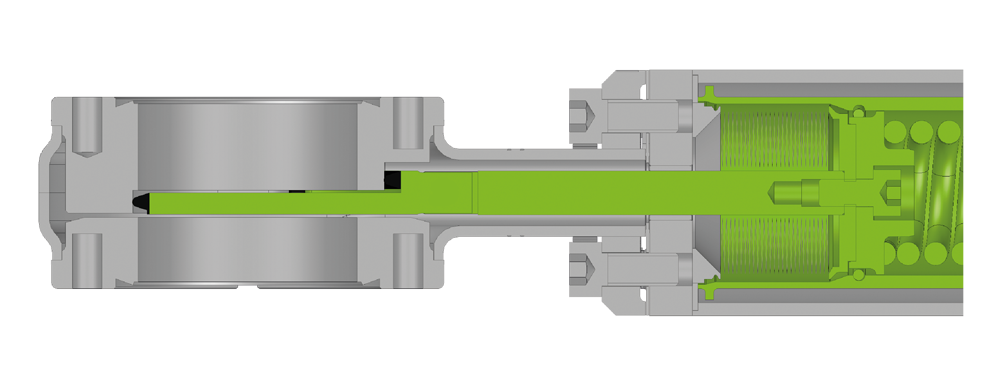

Read moreThe 01.0 Mini UHV Gate Valve series works with VAT’s patented MONOVAT technology which is specially developed to provide reliable gate sealing without any friction. With the MONOVAT technology the seal is vulcanized to the gate to provide a more reliable and durable sealing combined with superior performance in terms of low particle generation and outgassing.

The special soft closing mechanism of the MONOVAT minimizes potential shock effects to the process caused by a fast moving gate touching the valve body.

Free of lubricants, no valve mechanism in vacuum, a bake out temperature up to 250 °C and special cleaning options eliminate risks of process contamination.

With its modular design and its various design options, the 01.0 series can be tailored to nearly every requirement - even after installation - giving numerous update options, e.g. in different actuation or gates.

Already installed in thousands of demanding applications under various process conditions, the 01.0 series has proven its outstanding reliability. It has become the standard for UHV isolation in sizes from DN 16 – 50 mm (5/8" – 2").

The 01.0 Mini UHV Gate Valve is available in manual and pneumatic versions with solenoid valves either as an onboard solution or for external mounting. The solenoid valve’s standard voltage is 24 V DC but other voltages are available on request.

The valve position is indicated with a visual (mechanical) indicator. Standard options for flanges connectors are ISO-KF, CF-F. Customer specific flanges can be integrated.

The standard sealing material is FKM but other materials are available on request.

Special versions of the 01.0 for gas analysis provide bypass valves and orifice modules which are combined for a reliable and fixed pressure reduction. Window gates are also an option.

Features:

Benefits:

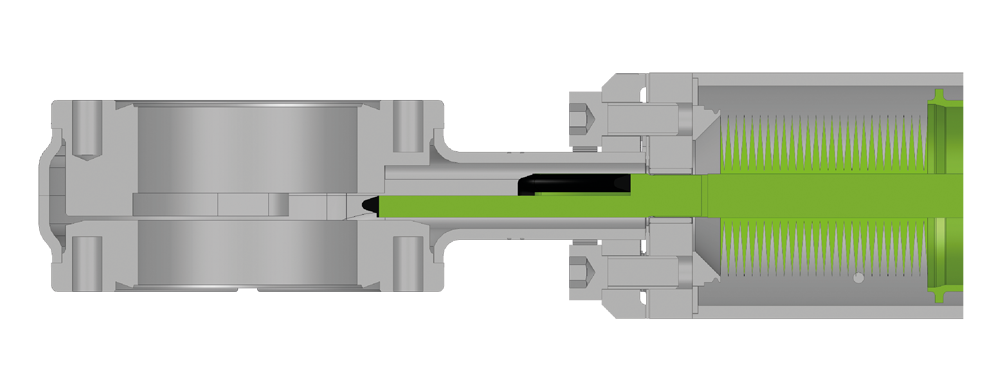

| 1 | Valve body with CF-F flange |

| 2 | Valve body with ISO-KF flange |

| 3 | Manual actuator |

| 4 | Manual actuator with position indicator |

| 5 | Pneumatic actuator: single acting with closing spring (NC) or single acting with opening spring (NO) |

| 6 | Pneumatic actuator: double acting, mechanically locked |

| 7 | Position indicator for 80 °C (standard) |

| 8 | Position indicator for 200 °C (option) |

| 9 | 3/2-way solenoid valve |

| 10_ | 4/2-way solenoid valve |

| Sizes | DN 16 (⅝"), DN 25 (1’’), DN 40 (1½’’), DN 50 (2’’) | ||

|---|---|---|---|

| Actuator | Pneumatic | Single acting with closing spring (NC) or opening spring (NO), or double acting |

|

| Manual | With turning handle | ||

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | ISO-KF, CF-F | ||

| Leak Rate | Valve Body | < 5 × 10-10 mbar ls-1 | |

| Valve Seat | < 1 × 10-9 mbar ls-1 | ||

| Pressure Range | 1 × 10-10 mbar to 2 bar (abs) | ||

| Differential Pressure | On the Gate | ≤ 2 bar | |

| At Opening | ≤ 30 mbar | ||

| Cycles until first Service | 50 000 | ||

| Temperature | Valve Body | ≤ 250 °C open / ≤ 200 °C closed | |

| Pneumatic Actuator | ≤ 200 °C | ||

| Solenoid Valve | ≤ 50 °C | ||

| Position Indicator | ≤ 80 °C | ||

| Manual Actuator | ≤ 250 °C | ||

| Heating and Cooling Rate | ≤ 50 °C h-1 | ||

| Material | Valve Body | AISI 304 (1.4301), AISI 316L (1.4435) | |

| Mechanism | AISI 304 (1.4301) | ||

| Bellows | AISI 316L (1.4435) | ||

| Seal | Bonnet | Metal | |

| Gate | FKM (Viton®) | ||

| Mounting Position | Any | ||

| Solenoid Valve | Actuator with closing or opening spring | 24 VDC, 9.0 W (others on request) | |

| Actuator double acting | 24 VDC, 5.4 W (others on request) | ||

| Position Indicator: Contact Rating | Voltage | ≤ 250 VAC | ≤ 50 VDC |

| Current | ≤ 5 A | ≤ 3 A | |

| Valve Position Indication | Visual (Mechanical) | ||

Showing scientific research new ways with the help of new analysis methods - this is the noble goal of the Swiss company TOFWERK. To this end, TOFWERK...

Shooting an underground movie of real life Switzerland has a long tradition in underground engineering and is world-renowned for the construction of t...