Sub-Fab Systems

Sub-fab processes can be challenging: corrosive, abrasive, and toxic gases and/or condensation and high levels of by-products in the gas stream can al...

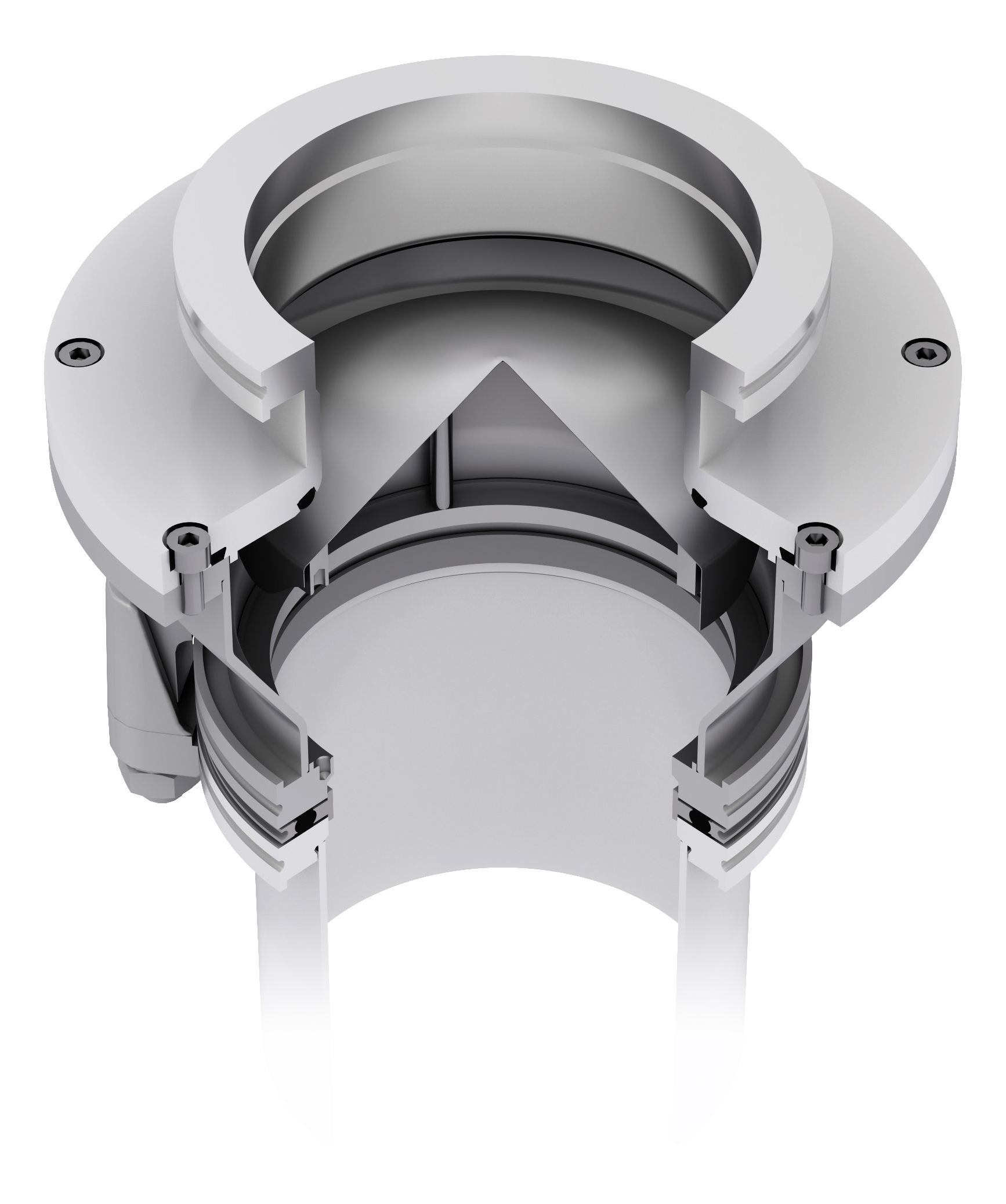

Read moreThe main requirement of a modern shut-off valve is its reliable and fast acting emergency isolation on any backflow event. The 25.7 is designed to provide a sensitive, high-speed isolation function that reliably prevents the risk of backflow into a process chamber or pipe system.

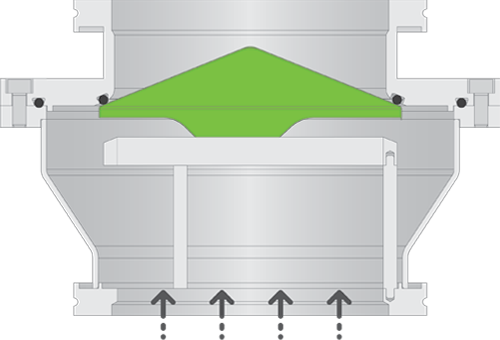

The 25.7 HV Quick Shut-Off Valve is flow controlled. The direct operating design without any subsystem (sensor and actuator) provides high-speed isolation with low complexity and low failure risk. With less than 10 milliseconds from the initial backflow impulse to full isolation the 25.7 leads its class.

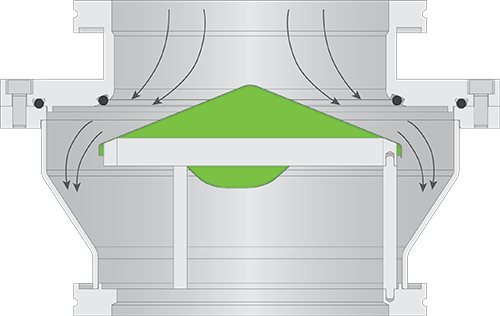

As a safety solution, a shut-off valve should ideally add no conductance barrier to the system. The 25.7’s special flow-optimized design sets the standard in this regard, delivering a perfect balance between high conductance and fast isolation.

When used in processes with by-products in the gas stream, e.g. foreline applications, any accumulation of contamination on a quick shut-off valve reduces conductance and can negatively influence its isolation capabilities. This process related challenge is adressed by a special surface coating which minimizes accumulation for most by-products significantly. An additional heating option is available to avoid process gas condensation at the valve surface.

open

emergency closure in case of backflow

closed

The 25.7 HV Quick Shut-Off Valve is available in sizes from DN 50 - 160mm (2“ - 6”). The valve body is made of stainless steel. The standard flange is ISO-K for DN63 to DN160 (2½ “ - 6”) and ISO-KF for DN50 (2“).

For applications with very aggressive process gases, FFKM seals are available.

Features:

Benefits:

| Sizes | DN 100 (4"), DN 160 (6") | ||

|---|---|---|---|

| Body Material | Stainless Steel | ||

| Standard Flanges | ISO-K | ||

| Leak Rate | Valve Body Valve Seat |

< 1 × 10-9 mbar ls-1 < 1 × 10-6 mbar ls-1 |

|

| Pressure Range | Vacuum to 1.2 bar (abs) | ||

| Differential Pressure | On the Gate | ≤ 1 bar | |

| Conductance (laminar flow) | DN 100 DN 160 |

6000 ls-1 |

|

| Cycles until first Service | recommended after each backflow event or with regular maintenance cycles |

||

| Temperature | Valve Body | ≤ 200 °C | |

| Heating and Cooling Rate | ≤ 50 °C h-1 | ||

| Material | Valve Body Gate |

AISI 304 (1.4301) AISI 304 (1.4301) |

|

| Seal | Bonnet Gate |

FKM FKM |

|

| Mounting Position | Fore line installation vertical only gate facing chamber |

||

| Trigger Pressure | ΔP at the Gate | ≥ 5 mbar | |

| Closing Time | Gate Move Time DN 100 DN 160 |

≤ 10 ms ≤ 15 ms |

|

| Weight |

DN 100 |

3.7 kg / 8.16 lbs 6.3 kg / 13.9 lbs |

|