Sub-Fab Systems

Sub-fab processes can be challenging: corrosive, abrasive, and toxic gases and/or condensation and high levels of by-products in the gas stream can al...

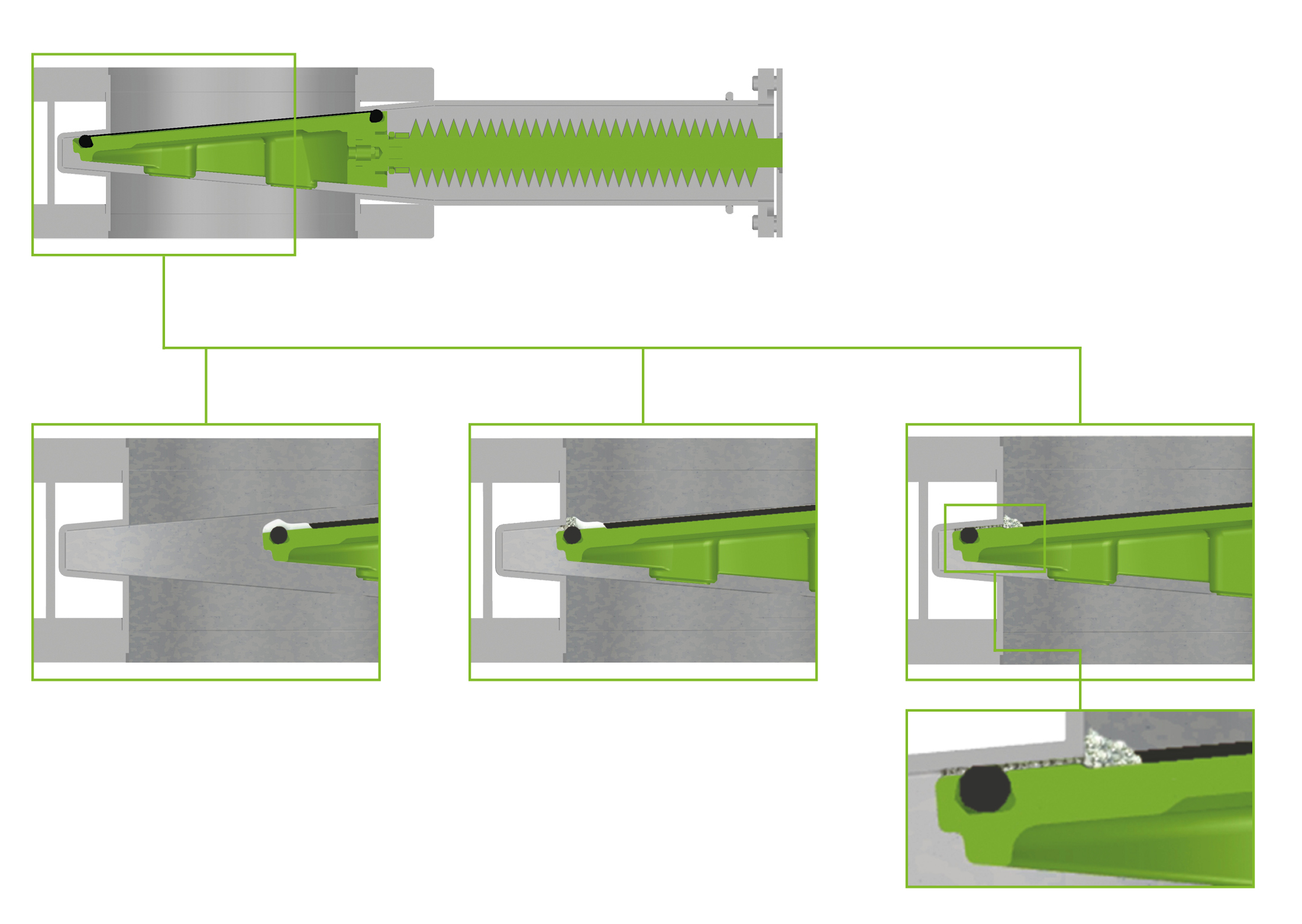

Read moreHigh proportions of by-products in the gas flow can lead to valve malfunctions as well as unplanned maintenance work due to the formation of deposits. The 09.1 HV Gate Valve with Wedge Design prevents this. Thanks to its special wedge design with self-cleaning function, it closes and opens reliably even if there are heavy deposits on the valve seat. Due to the wedge-shaped design of the gate, possible deposits are specifically pushed off the valve seat or the gate seal to always guarantee a reliable sealing.

The 09.1 HV gate valve is fully functional at up to 1 bar differential pressure.

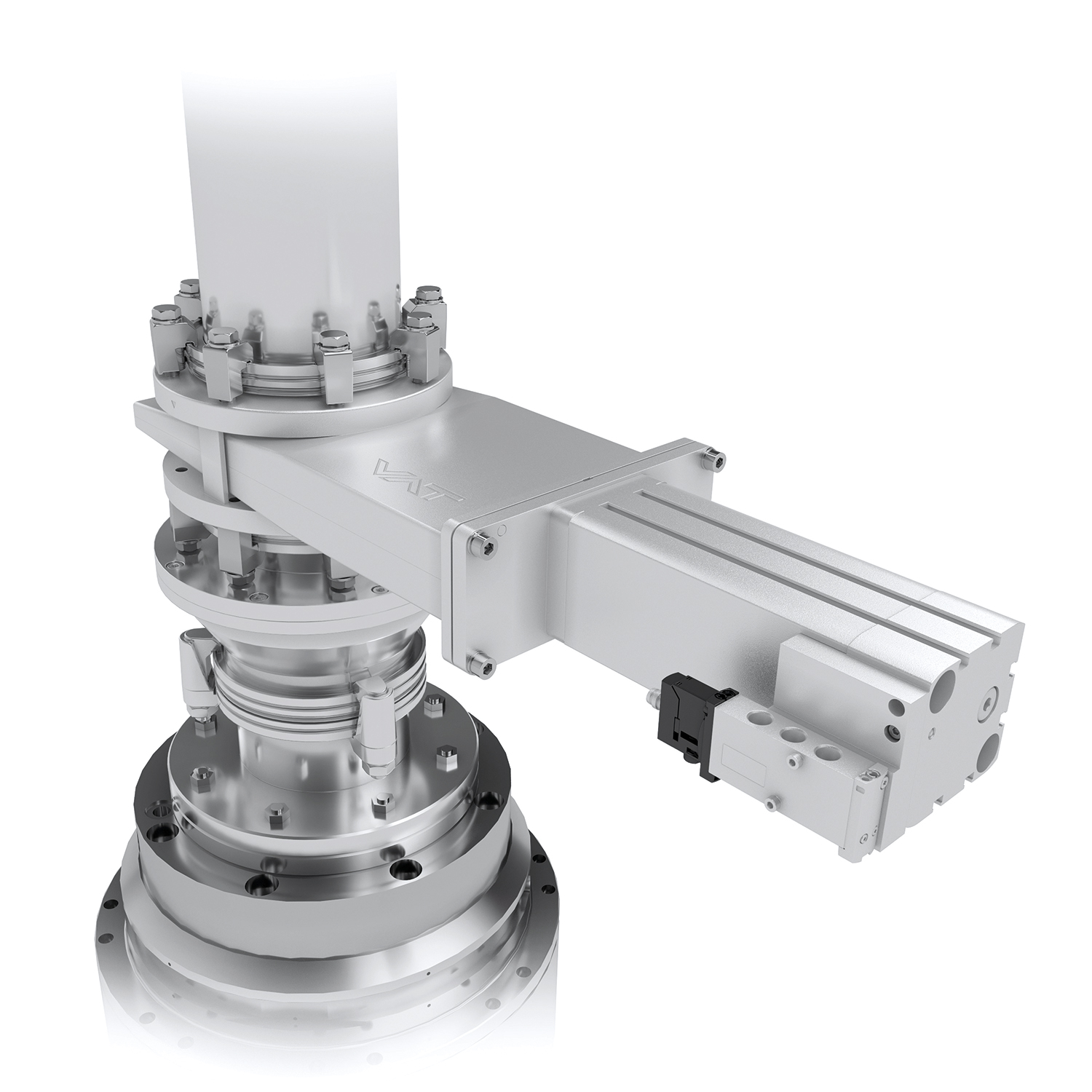

Already installed in thousands of demanding applications under various process conditions, the 09.1 HV gate valve with wedge design has proven its outstanding reliability. Especially in sub-fab applications, it has become the standard solution for vacuum pump isolation. Thanks to a wide range of design options, the gate valve can be easily integrated into any application.

The 09.1 HV gate valve with wedge design is available in manual and pneumatic versions. The standard voltage of the control valve is 24 VDC. For flange connections, customer-specific flanges are possible in addition to ISOKF, ISO-F, CF-F, ASA-LP or JIS. The standard O-ring material is FKM, but other materials are available upon request. In addition, the integration of a soft-pump function is an option as well as providing additional access points for e.g. measuring instruments.

Features:

Benefits:

| Sizes | DN 50 (2"), DN 63 (2½’’), DN 80 (3"), DN 100 (4"), DN 160 (6"), DN 200 (8") | ||

|---|---|---|---|

| Actuator | Pneumatic | Double acting | |

| Manual | With crank handle | ||

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | ISO-KF, ISO-F, CF-F, ASA-LP, JIS | ||

| Leak Rate | Valve Body | < 1 × 10-9 mbar ls-1 | |

| Valve Seat | < 1 × 10-7 mbar ls-1 | ||

| Pressure Range | 1 × 10-8 mbar to 1.2 bar (abs) | ||

| Differential Pressure | At Gate | ≤ 1.2 bar | |

| At Opening | ≤ 1 bar | ||

| Cycles until first Service | 5000 | ||

| Temperature | Valve Body | ≤ 180 °C | |

| Actuator | ≤ 100 °C | ||

| Solenoid Valve | ≤ 50 °C | ||

| Position Indicator | ≤ 70 °C | ||

| Material | Valve Body, Gate | AISI 304 (1.4301) | |

| Bellows | AISI 633 (AM350) | ||

| Seal | Bonnet, Gate | FKM (Fluoroelastomer) Optional: FFKM |

|

| Mounting Position | Any | ||

| Solenoid Valve | 24 VAC/DC, 1 W | ||

| Position Indicator: Contact Rating |

Voltage |

24 VAC/DC |

|