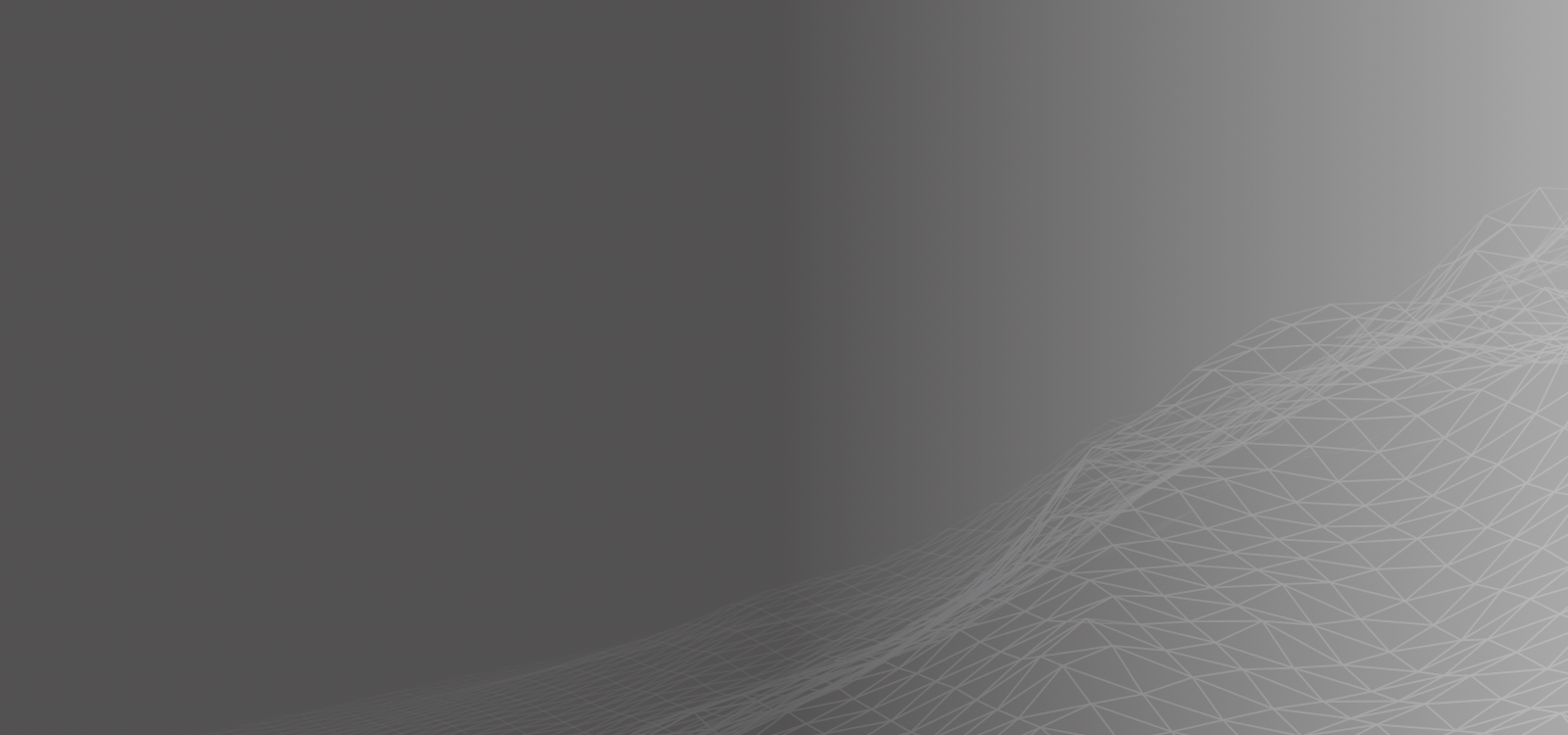

The Compact, Economic Alternative to Traditional Gate Valves

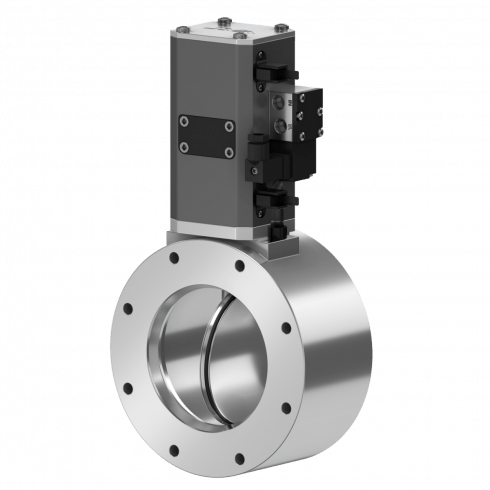

The key element of the 20.4 VATTERFLY Valves is the special VATterfly technology. The VATterfly closing mechanism operates significantly differently to conventional butterfly technology. During the closing cycle, the plate is moving without any contact with the valve body, avoiding any risk of activating potential particles, e.g. particles that have accumulated from gas by-products. It can also be mechanically locked in the open and closed positions similar to a gate valve for additional safety.

These features make the 20.4 especially suitable for isolation requirements in contaminating and aggressive processes. Tested in thousands of demanding applications under various process conditions the 20.4 series has proven its outstanding reliability.

The 20.4 VATTERFLY Valves are available in an extended body version (20.4) in which the plate rotation is covered by an extended body on the downstream side.

The valves are available in sizes DN 63 – 200mm (2½” – 8”) with valve bodies in stainless steel or aluminum. Both versions come with either ISO-KF or CF-F flanges as standard but other flanges can be supplied. The actuation is double-acting pneumatic with a 24 VDC solenoid valve although other voltages can be specified.

Key features of the 20.4 VATTERFLY Valve

Features:

- Low level of particle activation

- Resistance against process contamination

- Mechanical locking in open and closed positions

Benefits:

- High uptime in contaminating and aggressive processes

- Reliable operation

- Lower cost of ownership compared to traditional gate valve solutions

Technical data

| Sizes | DN 63 (2 ½"), DN 100 (4"), DN 160 (6"), DN 200 (8") | ||

|---|---|---|---|

| Actuator | Pneumatic | Double acting | |

| Body Material | Aluminum or Stainless Steel | ||

| Feedthrough | Rotary Feedthrough | ||

| Standard Flanges | ISO-F, CF-F | ||

| Leak Rate | Valve Body | < 1 × 10-9 mbar ls-1 | |

| Valve Seat | < 1 × 10-9 mbar ls-1 | ||

| Pressure Range | 1 × 10-8 mbar to 2 bar (abs) | ||

| Differential Pressure on the Gate | In Opening Direction | ≤ 1.2 bar | |

| In Closing Direciton | ≤ 1.6 bar | ||

| Differential Pressure at Opening | ≤ 500 mbar | ||

| Cycles until first Service | 100 000 | ||

| Temperature | Valve Body | ≤ 120 °C (150 °C optional) | |

| Actuator | ≤ 120 °C | ||

| Solenoid Valve | ≤ 50 °C | ||

| Position Indicator | ≤ 80 °C | ||

| Material | Aluminium Valve Body, Plate | EN AW-6060 (3.3206), AW-6061 (3.3211), AW-6063 (3.3206), AW-6082 (3.2315) | |

| Stainless Steel Valve Body, Plate | AISI 304 (1.4301) | ||

| Mechanism | AISI 316L (1.4435), AISI 304 (1.4301) | ||

| Support ring: Standard | POM | ||

| Support ring: 150 °C Option | PEEK | ||

| Seal | Bonnet, Plate, Feedthrough | FKM (Viton®) | |

| Mounting Position | any | ||

| Solenoid Valve | 24 VDC, 7.6 W (others on request) | ||

| Position Indicator: Contact Rating | Voltage | ≤ 50 V AC / DC | |

| Current | ≤ 0.5 A | ||

| Power | max. 10 W | ||