Synchrotrons & Accelerators

Synchrotrons and accelerators usually operate with large vacuum volumes in the UHV or XHV range. Having high demands on a physically inert behavior of...

Read moreThe main requirement of a fast closing valve is to react fast and reliable in case of air inrush. A loss of an UHV or XHV environment through leakage, especially in large volumes like accelerators or storage rings can lead to significant problems in terms of contamination and the effort to be taken to restore the required vacuum level.

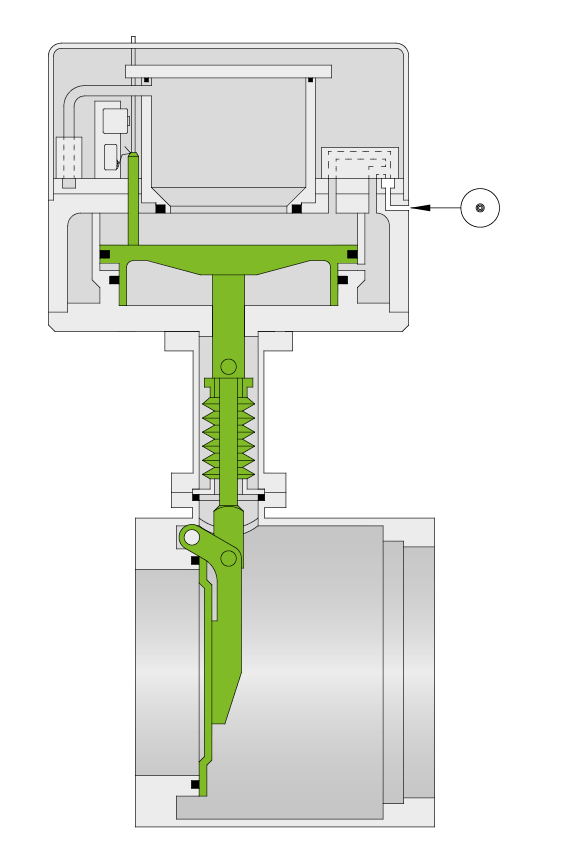

The 75.0 UHV Fast Closing Valve series protects vacuum levels with a fast closing reaction in case of a pressure rise. With below 10 milliseconds (depending on the valve diameter), the series closes vacuum lines in an outstanding fast speed. After the closure the valve is leaktight < E-9 mbarl/s. As any millisecond counts in preventing the degree of damage, the 75.0 sets the benchmark for protection.

The 75.0 is designed as flap valve (DN 63 – 200) and is pneumatically actuated. The standard bake out temperature is max. 200°C for valve body and max. 50°C for the actuator. The bonnet is metal sealed, the gate seal is FKM and a welded metal bellows seals the feedthrough.

The fast closing valve is controlled by a separate controller. The controller ensures the fast closing time by regularly checking the readiness status of the system, the sensor(s) and the connection to them. The controller is modular and can be configured for different valve/sensor arrangements. The status of the fast closing valve is also provided by the controller for remote output. Vice versa, the valve can be remotely controlled via interfaces on the controller.

Already proven in all leading accelerators and storage ring facilities under various process conditions, the 75.0 UHV Fast Closing Valve series has become the standard for reliable UHV and XHV system protection.

The 75.0 UHV Fast Closing Valve series body material is stainless steel. The standard flange connector is CF-F. Customer specific flanges are an option.

The series has a radiation resistance of 108 Gy for the valve body, < 105 Gy (option 106 Gy) for the gate seal and 104 Gy for the pneumatic actuator.

Standard time until first service is 2000 cycles, which means the valve series is for its purpose practically maintenance free.

| Sizes | DN 63 (2½"), DN 100 (4"), DN 160 (6"), DN 200 (8") | ||

|---|---|---|---|

| Actuator | Pneumatic | Double acting | |

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | CF-F | ||

| Leak Rate | Valve Body | < 1 × 10-10 mbar ls-1 | |

| Valve Seat | < 1 × 10-9 mbar ls-1 | ||

| Pressure Range | 1 × 10-10 mbar to 2 bar (abs) | ||

| Cycles until first Service | 2000 | ||

| Bake-Out Temperature | Valve Body | ≤ 200°C | |

| Actuator | ≤ 50 °C | ||

| Radiation Restistance | Valve Body Plate Seal Pneumatic Actuator |

108 Gy < 105 Gy (option: 106 Gy) 104 Gy |

|

| Material | Valve Body | AISI 316L (1.4435) | |

| Mechanism | AISI 316L (1.4435) | ||

| Gate / Plate | Titanium | ||

| Bellows | AISI 316L (1.4404, 1.4435) | ||

| Seal | Bonnet | Metal | |

| Gate / Plate | FKM (Viton®) | ||

| Mounting Position | Seat Side (marked) in opposite direction of the air inrush |

||