Get to the Next Performance Level

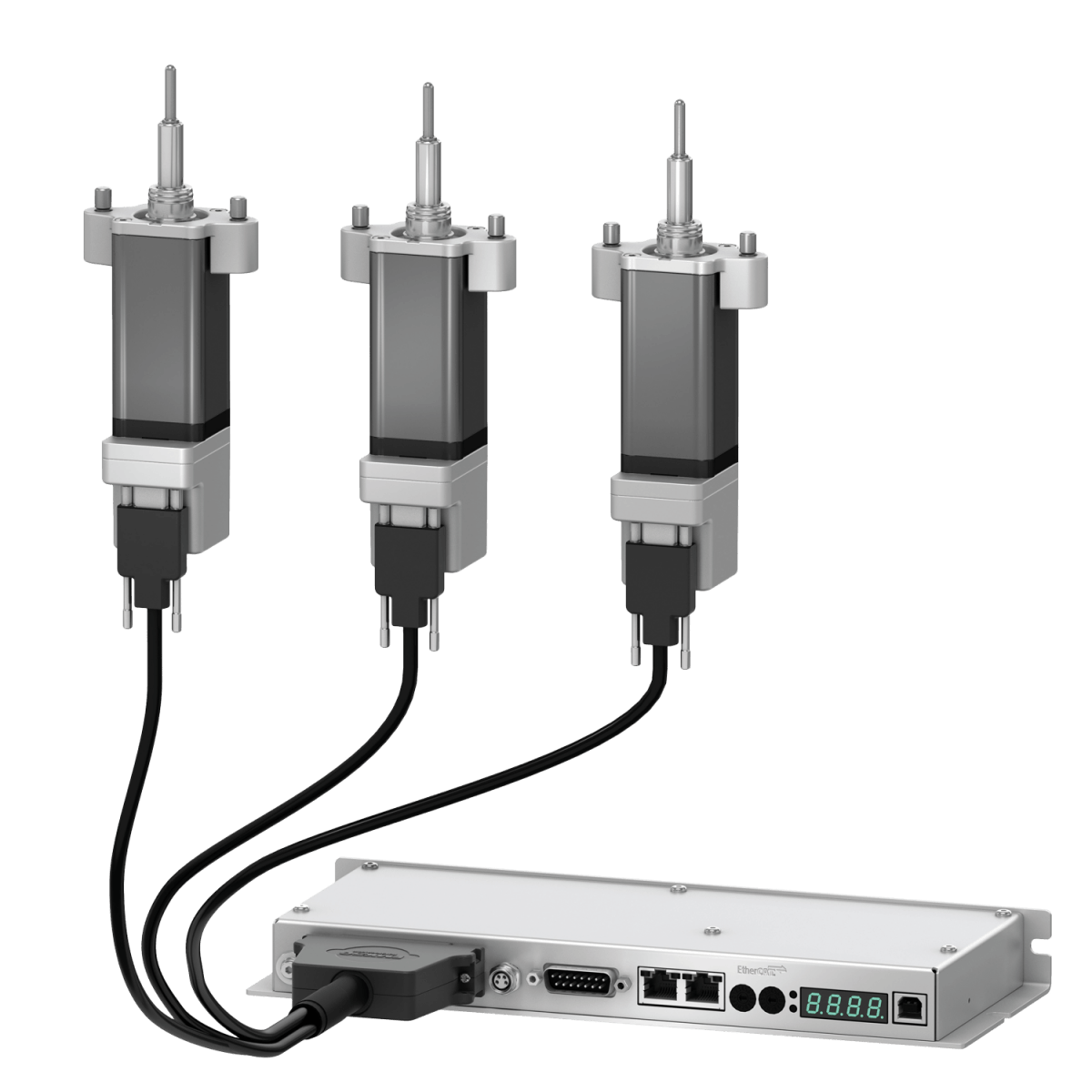

The 98.0 Mechatronic Wafer Lift Systems from VAT combine the latest actuation, control, material and sealing technology to create a simpler and smarter solution for wafer handling systems in all areas of semiconductor manufacturing. The key function is to provide precise, fast wafer movement, with the smoothest possible motion profile.

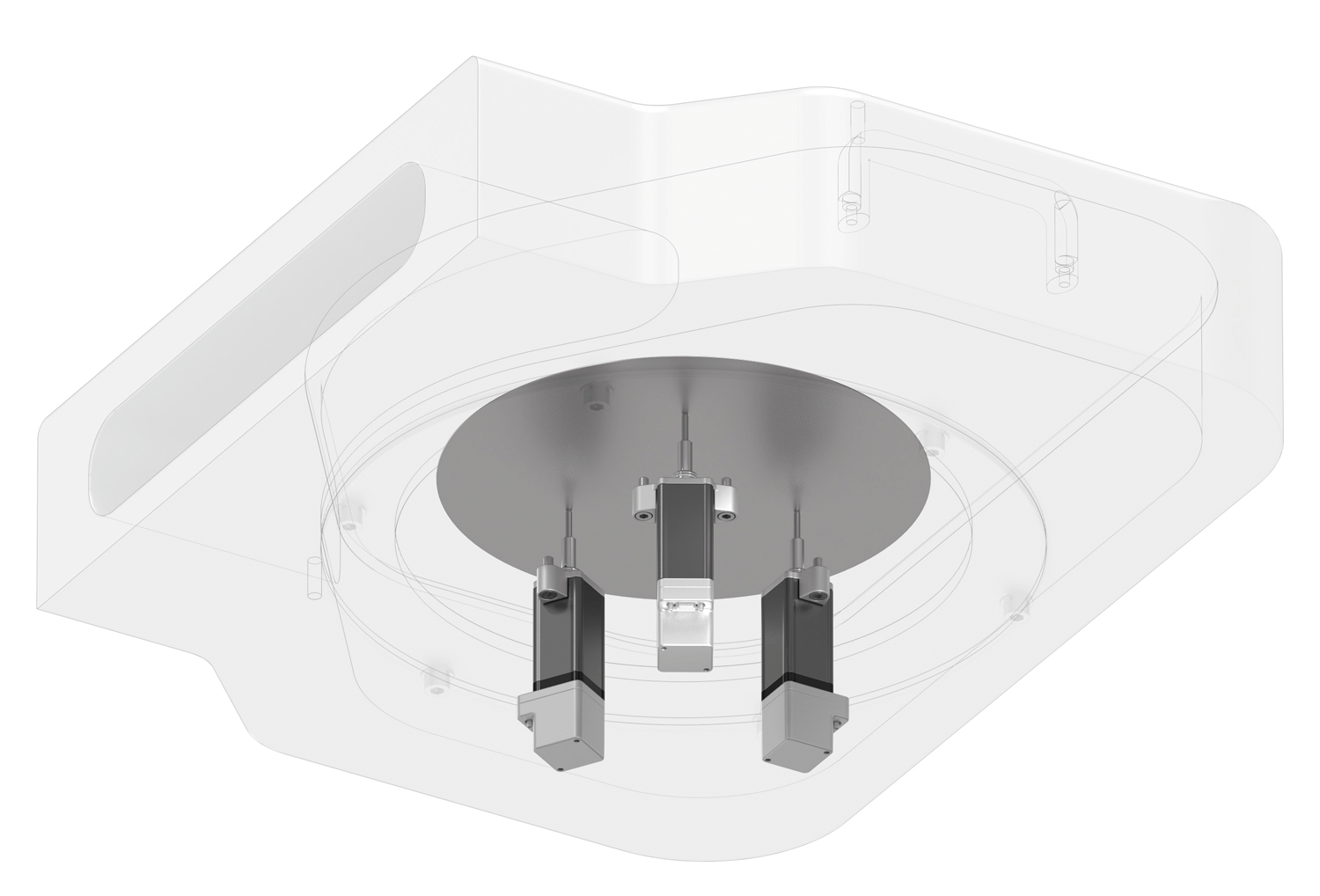

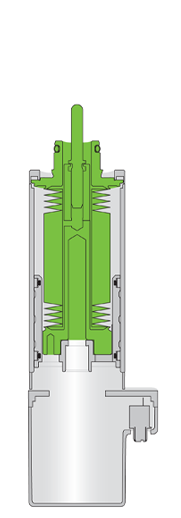

Built on the technology behind VAT’s newest generation of fast mechatronic valves and motion components, the motion profile of the wafer lift system is fully programmable for superior control. A key element is that the start and end position can be controlled flexibly and are not defined by a mechanical hard stop. Allowing easy control adjustments without mechanical inventions. Additionally, the force and speed of the lift movement are controllable in any phase of the movement, providing a very precise, smooth and fast handling of the wafer.

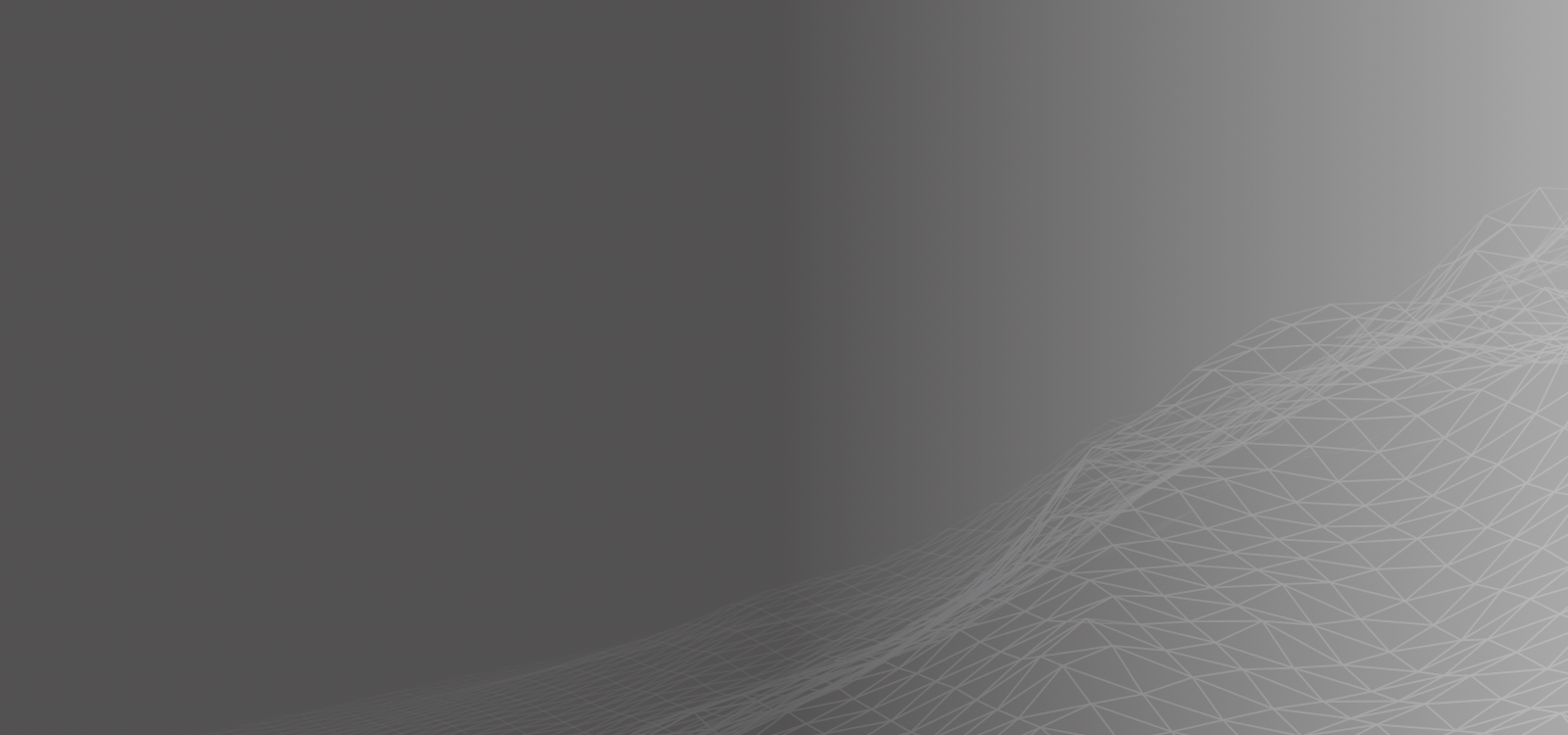

The 98.0 Mechatronic Wafer Lift System uses an IC2 (32-bit) controller with which all wafer lifts in any motion phase at any time are perfectly synchronized. The result is a very fast and at the same time very gentile lifting motion, repeatable and reliable even under harsh and changing process conditions.

The design of the 98.0 is focused on footprint minimization, obtained by three small, very compact independent actuated lifts, in opposition to solutions with a centralized actuator, which are more demanding to integrate. The central control unit of the system ensures absolute synchronized motion among the three lifts. An automated calibration procedure guaranties elimination of mechanical tolerances in the customer system or e.g., after a lift exchange.

The 98.0 Mechatronic Wafer Lift System is designed for maintenance-free operation and durability. The IC2 controller has an onboard control performance analyzer (CPA) that can be connected to any PC or PCU to monitor and change any performance setting of the lift system. With its anodized aluminum body as well as stainless steel bellows pin feedthrough sealing – optional in Ni-alloy for corrosive applications – the lift system is perfectly suited for various production environments.

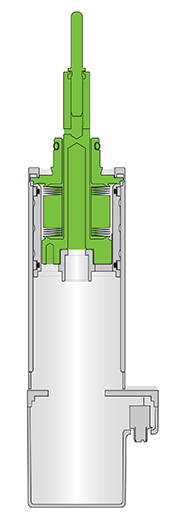

The 98.0 Mechatronic Wafer Lift System consists of three wafer lifts, the IC2 controller unit and the connecting cables between the lifts and the controller. The lifts are available in three options with 15, 30 and 60 mm stroke, other sizes on request. The lift actuators are BLDC motors with integrated brake and encoder. The pin feedthrough is bellows sealed. For wafer sticking and pressure detection a software add-on is available.

Key features of the 98.0 - Mechatronic Wafer Lift System

Features:

- Adjustable, multi-step motion profile

- Automated homing and calibration function

- Precise synchronized axis movement to reduce substrate shift

- Automated calibration procedure

- Complete electrical isolation of the drive unit

- State of the art IC2 controller with onboard CPA software

- Wafer sticking and pressure detection (on request)

Benefits:

- Fast, precise and save movement with minimized vibrations and shock

- Full motion control in any lift movement phase

- Reduced footprint

- High durability and reliability

Technical data

| Stroke | Up to 15 mm, 30 mm, 60 mm | ||

|---|---|---|---|

| Actuator | Brushless direct current motor (BLDC) with integrated brake and encoder |

||

| Feedthrough | Bellows | ||

| Leak rate | With FKM O-ring | < 1 x 10-8 mbar ls-1 | |

| Pressure range | 1 x 10-8 mbar to 1 bar (abs) | ||

| Speed | Up to 50 mm/sec | ||

| Cycles | Up to 3 million (AM350 bellows) | ||

| Temperature | Top Flange | 0 °C – 90 °C (Different temperature range on request) | |

| Material | Bellows Membrane Bellows End Piece Housing Top Flange Insulation |

AM350 (Ni alloy optional) AISI 316L EN AW-6060 EN AW-6082 T6 PPS GF40 |

|

| Seal | FKM | ||

| Position indicator | Incremental encoder 1024 – 4096 imp (4096 – 16384 qc) | ||

| Mounting position | Vertical, actuator down | ||

| Standard flange | S 980 DN special bonnet flange | ||

| Lubrication | Guide and Cylinder | Vacuum grease | |

| Load | Axial Torsional |

Max. 5N per axis under vacuum (higher load on request) not allowed |

|

| Break actuation time | < 25 ms | ||

| Behavior in case of power failure | Actuator Extended Actuator Retracted During Actuation |

Break engages Break engages Break engages |

|

| System consists of | Wafer lifts IC2 Controller Connecting Cable Set |

Article no. 980XX-S..52-…. Article no. 980EC-24GU-…. Article no. 980CV-99..-…. |

|

| Integrated system features | With IC2 Controller | Homing, calibration, synchronized axis movement | |

| Single lift weight | Max. 0.6 kg / 1.3 lbs | ||