Substrate Transfer

Semiconductors are produced in several steps in specially designed process chambers. Transfer valves play a decisive role in the transfer from one pro...

Read moreParticle performance in terms of a low degree of particle activation and particle emission as well as fast, reliable opening and closing cycles are the key performance indicators for atmospheric transfer doors in semiconductor production systems.

The new 07.0 HV Transfer Door Insert with LINVAT combines both exceptional particle performance with optimized controllability for adjustable, fast cycle times.

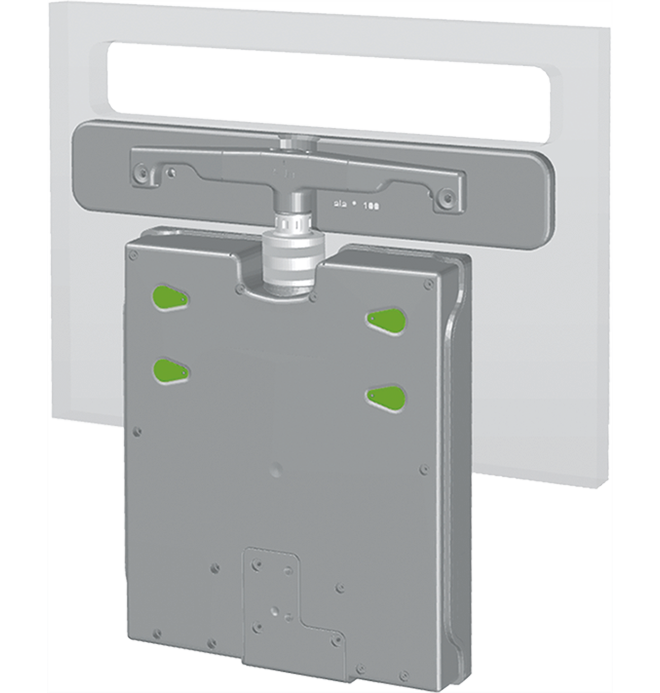

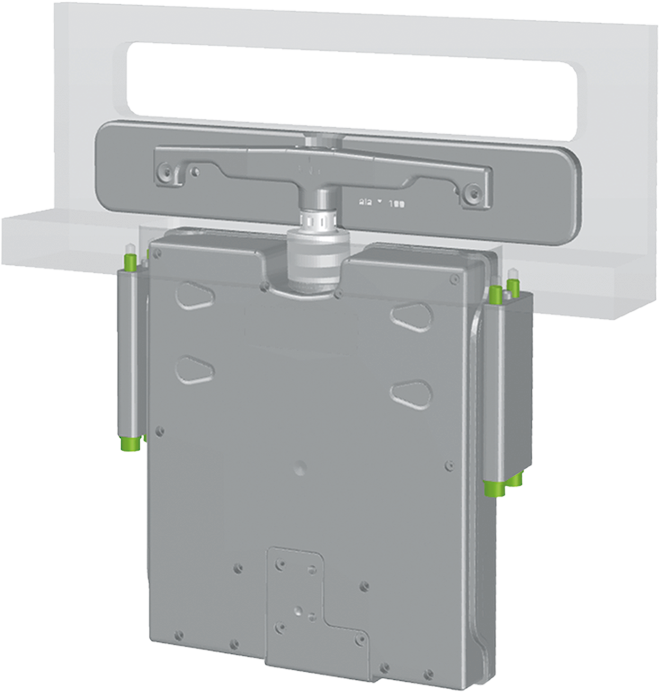

Installation options

The design of the 07.0 HV Transfer Door Insert with LINVAT technology focusses on optimized particle performance and high speed cycle times.

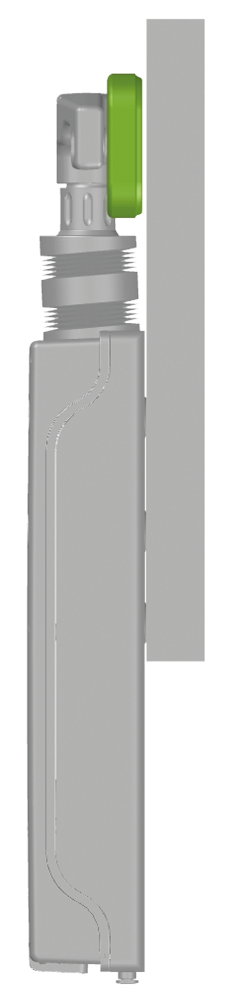

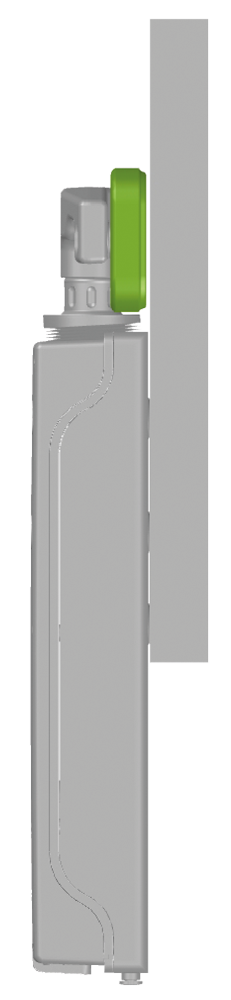

An outstanding level of particle performance is achieved by optimization of various design features like a torsion bar on the plate for uniform seal compression, a fully encapsulated actuator, a lubrication free environment and a real L-Motion with an adjustable speed profile to avoid any closing shock.

The exceptional real L-Motion with an adjustable speed profile of the 07.0 is achieved by VAT’s special LINVAT technology. Instead of two separate actuators for the vertical and horizontal movement of the L-Motion, LINVAT achieves this with only one actuator in a twostep motion. The result: a highly reliable actuators concept with a fast, stable, adjustable and shock free movement. The benefit: Higher uptime and improved controllability.

Features:

Benefits:

| Sizes |

DN 10 mm (1.81" × 9.29") |

||

|---|---|---|---|

| Actuator | pneumatic | ||

| Feedthrough | bellows | ||

| Leak Rate | < 1 × 10-7 mbar ls-1 | ||

| Differential Pressure at the Gate | in closing direction | ≤ 1 bar | |

| in opening direction | ≤ 0.1 bar | ||

| Differential Pressure during opening | ≤ 30 mbar | ||

| Cycles until first Service | ≥ 3 million | ||

| Actuation Time | Opening | ≤ 1 s | |

| Closing | ≤ 1 s | ||

| Temperature | at Gate | ≤ 120 °C | |

| at Actuator | ≤ 80 °C | ||

| Material | Gate | aluminum | |

| Bellows Protection | Polytetrafluoroethylene | ||

| Seal | FFKM, vulcanized | ||

| Mounting Position | actuator up or down | ||

| Locking in case of pressurized air failure | pneumatic locking | ||

| Position Indicator | Reed Swith | ||

| Weight | DN 10, DN 12, DN 15 DN 14, DN 20 |

8.5 kg /18.7 lbs 7.5 kg /16.5 lbs |

|