Process Control & Isolation

High-precision control and isolation of vacuum and gas flows is essential in semiconductor manufacturing. In both upstream and downstream processes, a...

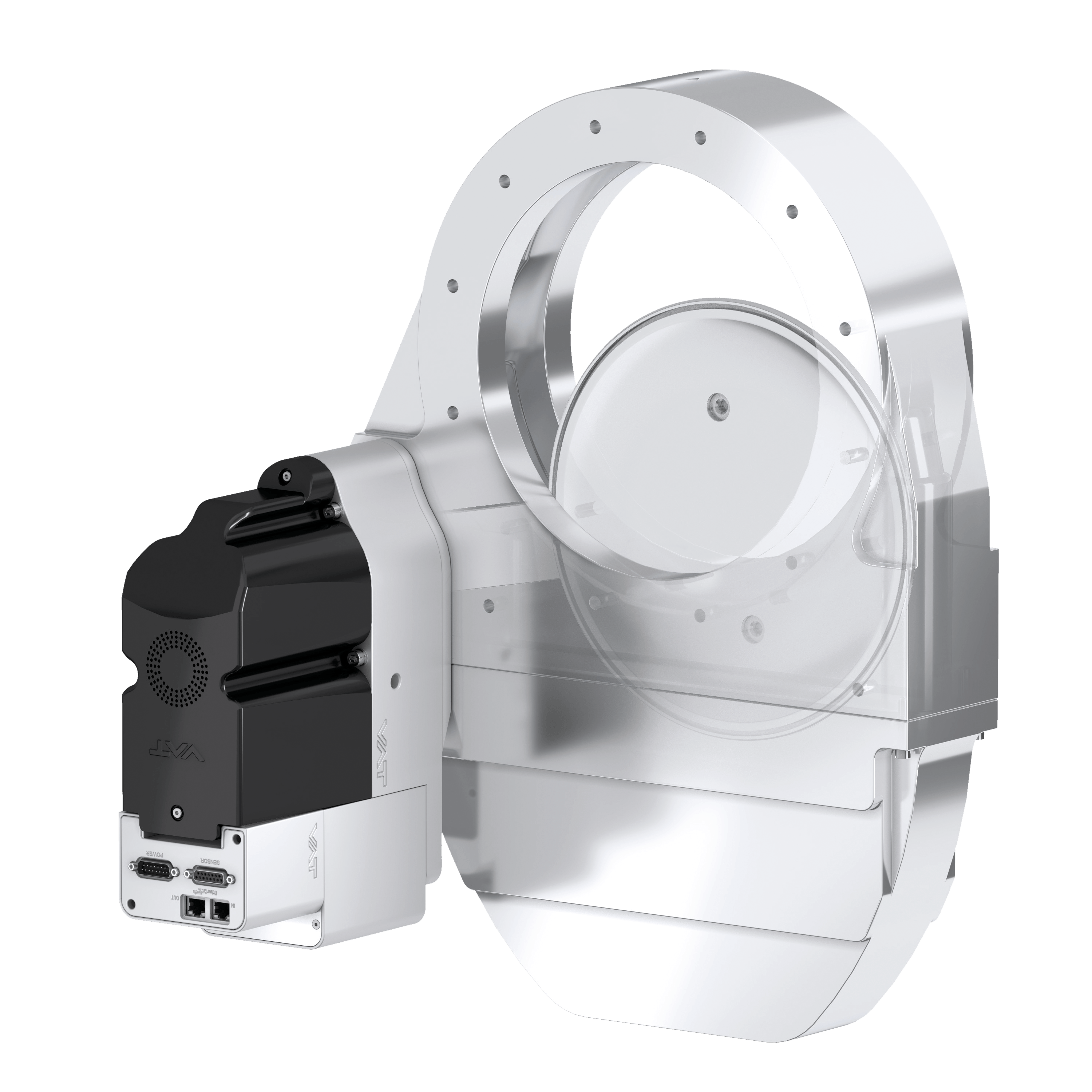

Read moreThe 65.5 HV Pendulum Control Valve provides an outstandingly high, controllable conductance spectrum. A key feature is also its exceptionally low particle count and low particle activation level due to its smooth open and close movement.

The valve was specifically designed for harsh processes such as corrosive etching and cleaning applications in semiconductor production processes where a highly controllable conductance spectrum is required with low initial controllable conductance.

The 65.5 is provided in DN 250mm (10”) and controls down to minimum conductance of only 2 l s-1. Increases in conductance can be controlled to a very fine degree due to the data processing capabilities of the 32-bit actuator controller. It also provides faster actuation, as sensor and control commands are processed faster than an equivalent 16-bit controller. Various standard port connectors on the controller provide easy access via PC or a connection to a process control unit.

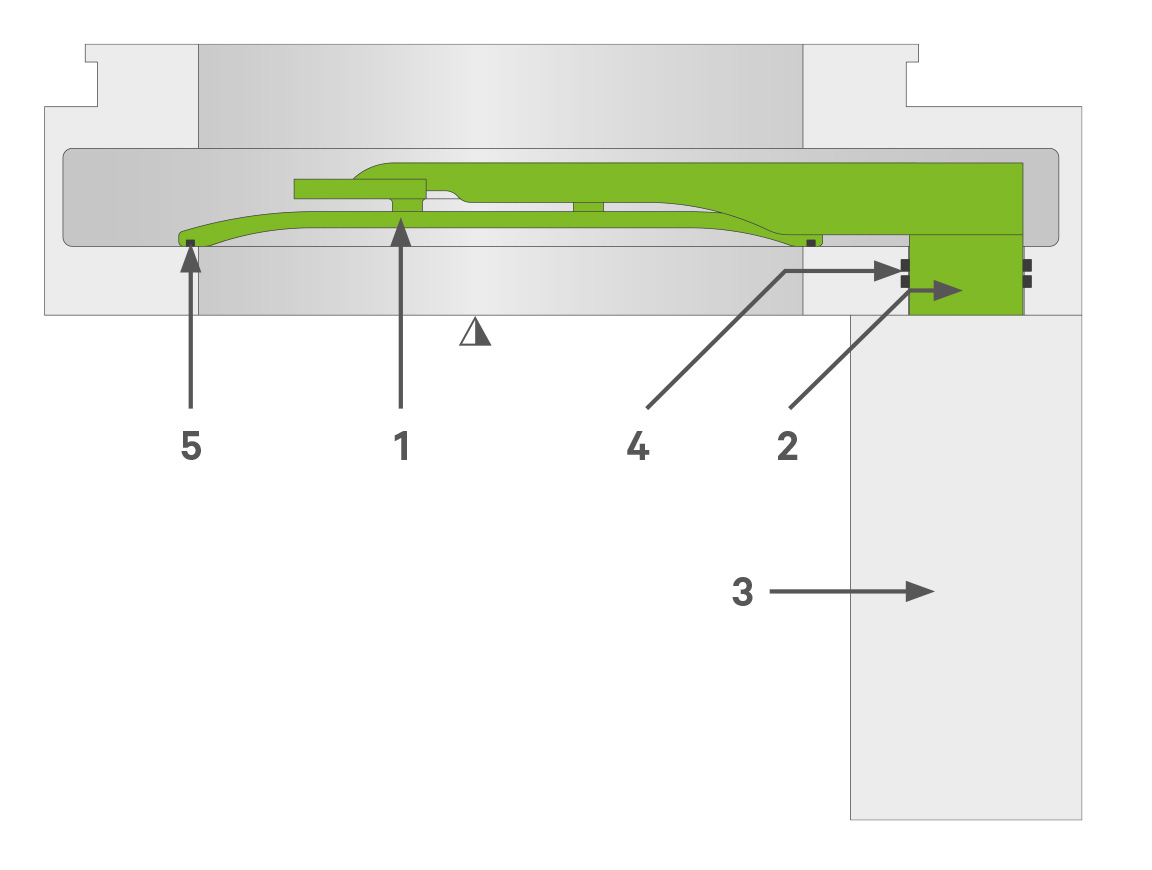

The pendulum gate mechanism has been designed to very robust to ensure that it resists any process by-products. To reduce seal wear and avoid particle generation as well as particle activation, the open and close movement is divided. The first degree of conductance is achieved by a vertical movement away from the gate seat and later increases in conductance is achieved by moving the pendulum gate in a horizontal movement. Due to the fine controllability of the gate movement the preset movement sequence can be adjusted to process requirements very pecise. To secure leaktight closing the gate is pressed to the gate seat with a special, patented pressure bar. This ensures an even sealing pressure in all areas of the gate.

With a compact design and direct mounting option as well as a variety of other design options, the 65.5 series is easy to integrate into various vacuum processes.

The 65.5 HV Pendulum Control Valve is available in blank or hard anodized aluminum with standard flange connectors in ISO-F and JIS. Customer-specific flanges can be integrated as well as a heater for valve operating temperatures of up to 120°C.

1. Gate

2. Actuator shaft

3. Two-axis actuator

4. Actuator feedthrough seal

5. Gate seal

| Sizes | DN 250 (10") | ||

|---|---|---|---|

| Actuator | Integrated pressure controller with servo drive | ||

| Body Material | Aluminum blank or hard anodized | ||

| Feedthrough | Rotary Feedthrough | ||

| Standard Flanges | ISO-F, JIS | ||

| Leak Rate Valve Body | Blank aluminium Hard anodized aluminium |

< 1 × 10-9 mbar ls-1 < 1 × 10-5 mbar ls-1 |

|

| Leak Rate Valve Seat | Blank aluminium Hard anodized aluminium |

< 1 × 10-9 mbar ls-1 < 1 × 10-4 mbar ls-1 |

|

| Pressure Range | Blank aluminium Hard anodized aluminium |

1 × 10-8 mbar to 1.2 bar (abs) 1 × 10-6 mbar to 1.2 bar (abs) |

|

| Cycles until first Service1) | Pressure Control Closing / Opening |

2 Million 50 000 |

|

| Temperature | Valve Body Controller |

≤ 120 °C Max. 50 °C (≤ 35 °C recommended) |

|

| Material | Valve Body, Plate | EN AW-6061 (3.2311) T651 | |

| Other Parts | AISI 316L (1.4404, 1.4435) | ||

| Connection screw at plate | SST A4-80, Ni-PTFE, coated | ||

| Seal | Bonnet, Plate Body Feedthrough | FKM (Viton®) | |

| Mounting Position | Any | ||

1) Maximum values depending on operating conditions and sealing materials