Proton Therapy

Proton therapy as a medical treatment process is implemented in different technical concepts, with different requirements for the vacuum systems invol...

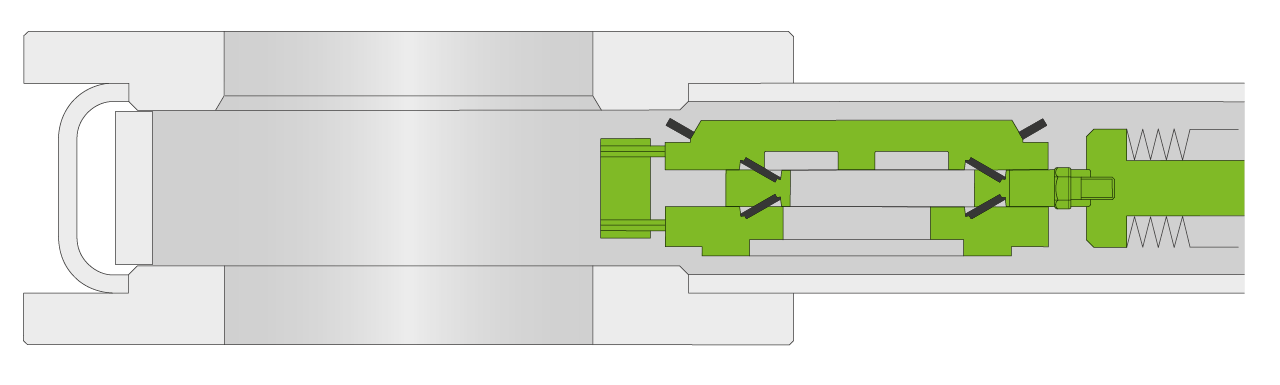

Read moreThe 48.2 UHV All-Metal Gate Valve series is designed for reliable isolation in UHV and XHV applications with high temperature environments at the valve of up to 300°C as well as for corrosive and condensing media. It can also resist radiation of up to 108 Gy.

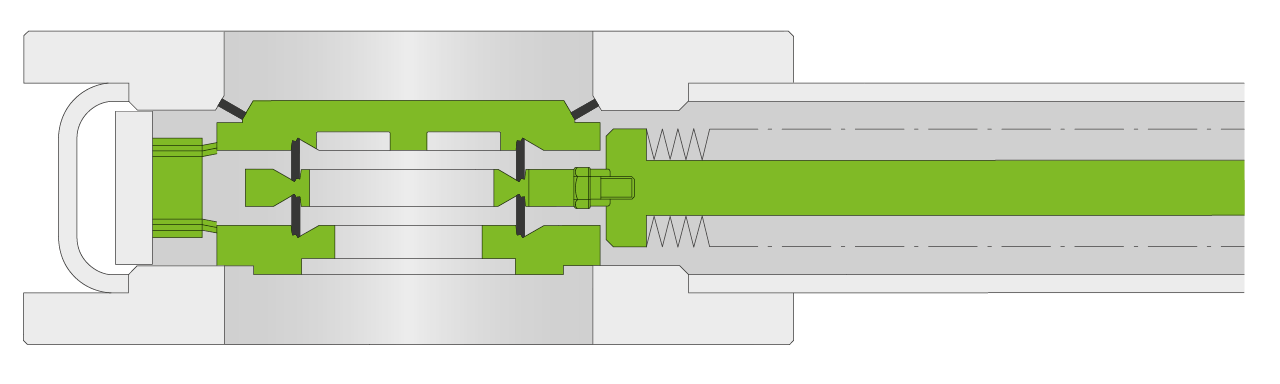

These all-metal gate valves are designed for maximum conductance and they are equipped with VATRING "hard on hard" sealing technology. This dynamic all-metal sealing system is characterized by consistent reliable sealing and constant closing forces. It enables high sealing forces with comparable low axial forces. The sealing partners are made from stainless steel and they deform elastically only. The 48.2 XHV All-Metal Gate Valve series are designed and tested for a lifetime of 20 000 cycles (DN 16 – 200mm) and 5 000 cycles (DN 250 – 320mm). However, the sealing system is good for 100 000 leak tight closures in a clean vacuum environment.

Already installed in thousands of demanding applications under various process conditions, the 48.2 series has proven its outstanding reliability.

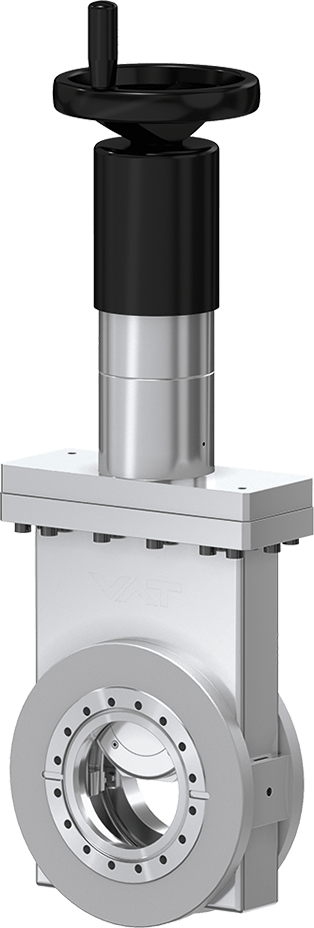

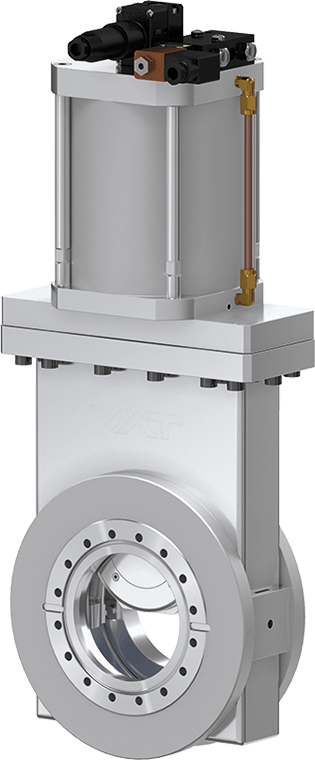

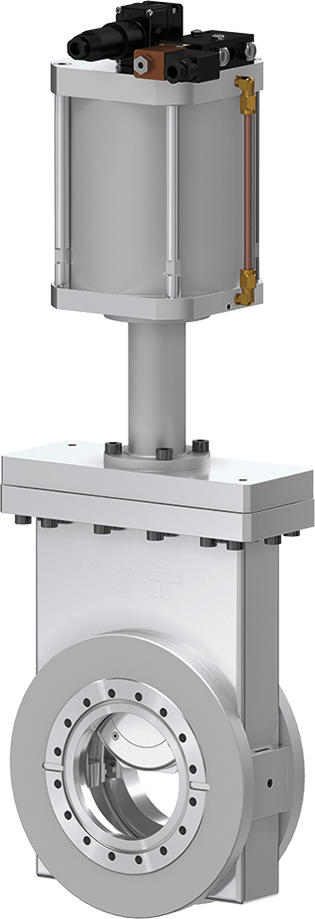

Various design options in actuation, flange connections or additional vacuum ports make it easy to integrate the valves into any vacuum application.

A key feature is the "hard on hard" VATRING sealing system, also used in other well-known VAT all-metal valves.

The valves are available from DN 16 to DN 320mm (5/8” - 12”). The standard flange is CF-F.

The distance between the gate body and the actuator can be extended to maximize the bake out temperature of up to 300 °C, in open and closed position. Gates with windows as well as ports for roughing, venting or for gauges are also part of the various design options.

Features:

Benefits:

| Sizes | DN 63 (2½"), DN 100 (4"), DN 160 (6") |

||

|---|---|---|---|

| Actuator | Manual | With handwheel | |

| Pneumatic | Double acting | ||

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | CF-F | ||

| Leak Rate | Valve Body | < 1 × 10-10 mbar ls-1 | |

| Valve Seat | < 1 × 10-10 mbar ls-1 | ||

| Pressure Range | XHV to 2 bar (abs) | ||

| Differential Pressure on the Gate | ≤ 2 bar | ||

| Differential Pressure at Opening | DN 63 – 250 | ≤ 500 mbar 1) | |

| Cycles until first Service | DN 16 – 200 DN 250 – 320 |

20 000 5 000 |

|

| Temperature | Valve Body | ≤ 300 | |

| Manual Actuator | ≤ 140°C (Option: 200°C) | ||

| Pneumatic Actuator | ≤ 200 °C | ||

| Solenoid Valve | ≤ 80 °C | ||

| Position Indicator | ≤ 80 °C (Option: 200 °C) | ||

| Heating and Cooling Rate | DN 16 DN 40 – 160 DN 200 – 320 |

≤ 80°C h-1 ≤ 50°C h-1 ≤ 25°C h-1 |

|

| Material | Valve Body | AISI 316L (1.4404, 1.4435) | |

| Mechanism | AISI 316L (1.4404, 1.4435) | ||

| Bellows | AISI 316L (1.4435) | ||

| Seal | Bonnet | Metal | |

| Gate | Metal | ||

| Mounting Position | DN 16 – 250 DN 320 |

Any On Request |

|

| Solenoid Valve | 24 VDC, 2.5 W (others on request) | ||

| Position Indicator: Contact Rating | Voltage | ≤ 50 VAC/DC | |

| Current | 80°C: ≤ 1.2 A | 200°C: ≤ 1 A | |

| Valve Position Indication | Visual (Mechanical) | ||

1) 1 bar with reduced number of cycles.

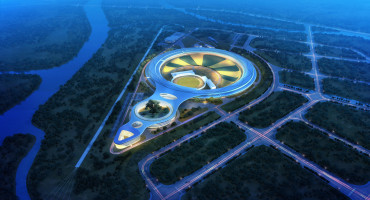

The Institute of High Energy Physics (IHEP) is China’s largest research institute for high energy physics. At IHEP, more than 1400 full-time employees...

Light has always been the most important tool for humanity to advance the understanding of nature. We only tend to believe what is visible to our eyes...

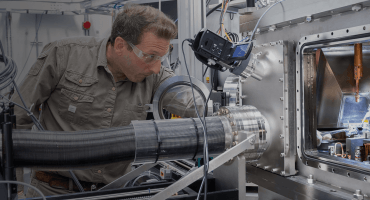

The light source at Argonne National Laboratory has been used by researchers and scientists from all around the world since March 1995. At its core, a...