VAT is known worldwide for supplying customers with specialized valve solutions for all sorts of applications. This wealth of experience is also reflected in an enormously broad standard portfolio of vacuum valves, which can be easily adapted to a wide variety of requirements by means of flexible variants, for example in terms of the flanges or the seal type.

But in the case of complex industrial plants or series production, this flexibility in the standard portfolio may not be sufficient, and tailor-made solutions may be necessary to cover specific customer requirements. In such cases, VAT offers so-called individual valve portfolios.

Tailor-made for our customers

Essentially, such customer- or project-specific portfolios consist of a selection of different valve types and technologies that are tailor-made according to the customer's specifications and then made available to global suppliers, for example. This ensures that all supplied plant modules always contain the same specific valves (identical parts strategy). Using the example of the ITER nuclear fusion plant, the advantages of valve portfolios and what needs to be taken into account when supplying them can be readily understood.

Since a high number of vacuum valves with very similar or identical requirements are installed in the big ITER plant, it made perfect sense to define the performance spectrum of the valves to be used as a whole, i.e., beyond the requirements of a single valve in a specific application. This portfolio approach makes it possible for even slight variations in operating conditions to be fully accommodated by as few variants as possible. To implement this approach, ITER entrusted VAT with the development of a uniform (all-metal and elastomer) valve portfolio in accordance with the ITER specifications.

Individually adjusted to the application spectrum

This was the birth of the so-called ITER catalog, a specific valve portfolio consisting of about 140 gate and angle valves that is precisely tailored to the demanding conditions of ITER. "The ITER catalog contains 14 different valve types, about half of them all-metal-sealed and the other half elastomer-sealed," explains Phil Schneider, the VAT product manager responsible for ITER. "In close consultation with those responsible for ITER, we have developed the catalog structure in such a way that the required performance spectrum is optimally covered and yet as few variants as possible are required."

The catalog is structured on the basis of the variants required by ITER, for example in terms of the valve size, the required connections, or the different operating principles. "This clearly shows that customer-specific portfolios are designed to perfectly match the individual application spectrum of the respective project or series production," adds Phil Schneider. The comparatively high number of variants in the ITER project is a result of the wide range of valve technologies required in the ITER plant, as well as the rather tight technical specifications for the individual areas of application. But Phil Schneider is satisfied with the result: "By precisely defining the valves' properties and by matching them exactly with the ITER requirements in advance, we have succeeded in standardizing the overall technical complexity of the valve requirements, in reducing the amount of detailed testing required during prototype development, and in making the individual valve variants available more quickly in terms of production and delivery."

Graphical representation of the ITER catalog, a portfolio of VAT valves designed specifically for ITER. On the right side are the valve types with elastomer sealing, and on the left are the all-metal-sealing valve types. Above are the gate valves, and below are the angle valves.

Source: PDF from Phil Schneider

Simplified procurement procedures

The ITER catalog is freely accessible via the VAT website. For example, ITER plant designers and ITER suppliers alike can view the variants available in the portfolio and conveniently place upcoming orders. All purchase and delivery modalities are defined via framework agreements, which greatly simplify the procurement.

All companies involved in the construction of ITER are obliged to make exclusive use of the ITER catalog when it comes to valves. Phil Schneider comments: "The whole point of such a portfolio is that all of the customer's variants have already been tested in detail and technically approved in advance. On the other hand, new variants introduced for each construction phase would complicate or massively prolong the completion process." In this way, the catalog ensures that the overall ITER facility can be assembled more quickly at the end of the day, because it consists of the same predefined components in all areas. "Such an identical parts strategy is particularly interesting for customers with complex large-scale projects or series production," Phil Schneider knows from experience.

Identical parts strategy

In such settings, a customer-specific valve portfolio such as the ITER catalog can show all its advantages: "ITER does not have to compromise on any of the particularly important performance characteristics, since the catalog components are optimized exactly for ITER requirements in terms of design, material, configuration, and connections," says Phil Schneider. In addition, the use of identical components reduces complexity not only in terms of the improved performance and plant safety, but also in procurement and logistics.

In this context, numerous administrative and manufacturing barriers can also be elegantly circumvented by the ITER catalog. "Things agreed in advance, such as clearly defined transport and cleanroom packaging, or uniform guidelines for the manufacturing processes, such as the cleaning stages in valve production, make the work easier for everyone involved, and spare parts management is also greatly simplified with such an identical parts strategy!" summarizes Phil Schneider.

The uniform documentation in the ITER catalog is another big plus for the customer. For example, each valve is documented in detail on the corresponding VAT website, with data sheet, dimensional drawing, operating instructions and the associated CAD envelope model. "At VAT, project- or customer-specific documentation is a natural part of our services," explains Phil Schneider. "Since we do this on a daily basis for a large number of customers, we can bundle the individual documentation steps into time- and cost-efficient processes."

Framework agreements reduce the workload

Also in terms of the documentation surrounding valve manufacture and delivery, the ITER catalog brings nothing but benefits to all parties involved. Thanks to the framework agreements, which predefine in detail all steps from ordering to delivery and price, individual orders from the portfolio can be extremely simplified and accelerated. In addition, ITER and its suppliers do not have to repeatedly care about compliance with the required product properties.

For example, when manufacturing the ITER valves, VAT automatically takes into account the high requirements regarding the quality of the stainless steel used for the housing flanges. "We include such criteria in the production process of the housing, and confirm this in the form of a 3.1 material certificate and a precise welding documentation. So for special material requirements of this kind, the ITER developers and their suppliers can sit back and relax while we at VAT reliably take care of the detailed work in the background!" says Phil Schneider, describing the great flexibility of the VAT range of services.

Reliable availability

On ITER's side, thanks to the valve portfolio, the administrative burden is significantly reduced; and ITER suppliers are pleased with clear specifications and easily ordered components in always the same high VAT quality. In return, of course, VAT has the responsibility to organize the procurement channels for all raw materials and semi-finished products in such a way that all ITER delivery requirements can be answered in a timely manner. "This responsibility is a core performance feature of customer-specific portfolios; in fact, in the vacuum valve market, this is one of VAT's unique selling points," Phil Schneider notes. But not only that! In fact, VAT guarantees all agreed product and delivery specifications as well as the price for a defined period of time, sometimes several years, depending on the customer's requirements.

"In the case of ITER, the discussions around the portfolio development began in 2014; currently, the term of the ITER catalog has been agreed until at least 2029. Once again, this demonstrates that companies working with VAT can enjoy reliable availability of the required valves for decades, and if necessary, also of spare parts in the necessary specification," explains Phil Schneider, naming another immense advantage of customer-specific VAT portfolios.

World's largest spectrum of technologies

When developing customer-specific portfolios, VAT can draw on the world's largest spectrum of vacuum valve technologies, with a large number of the used technologies being VAT's own developments. The extent to which existing technologies can be relied upon, or if completely new valves have to be developed, depends heavily on the requirements of the customer. "In some cases, the desired effect can be readily achieved based on the wide range of customization options in our VAT standard portfolio," says Phil Schneider.

The position indicators in the ITER valves are an apt example for this: Instead of the standard version with a heat resistance of 80°C, a modified detector was fitted that can withstand temperatures of up to 200°C. Also, the usual cable bundle was replaced by a special connector in accordance with the ITER standard to ensure effortless compatibility of the valves with the plant control system. The standard was also not sufficient for the elastomer-sealed valves, due to the comparatively high radiation intensity inside the plant. "Accordingly, all O-rings on the ITER valves are made of a particularly radiation-resistant EPDM elastomer," Phil Schneider describes the corresponding modification.

Product development included

The fact that VAT also offers product developments as a part of customer-specific portfolios is then demonstrated by the all-metal-sealed valves. For example, different flange types had to be integrated, and accordingly, in addition to the standard CF flanges and welded sockets, there is also the so-called ITER flange. "This flange is based on the principle of the Helicoflex double seal, where a tightly wound helical spring, surrounded by one or more metal rings, is designed to have a specific compression resistance," Phil Schneider explains in detail. The space between the rings can be evacuated via a socket on the flange, in order to detect possible leaks and thus penetrating tritium.

Speaking of tritium, this radioactive substance, which is to be used in the ITER plasma, must of course not be released into the atmosphere under any circumstances. In order to take this ITER-specific feature into account in the best possible way, VAT put all its vacuum experience into play for the ITER Type 1 UHV all-metal valve: "We constructed a second protective housing around the standard housing," explains Phil Schneider. "The space between the two housing layers can also be evacuated, and we installed a special port with the help of which the interspace vacuum can be monitored. If you regulate the vacuum in the interspace to about 500 mbar, then ITER staff can reliably detect possible leaks both in the direction of the ultra-high vacuum inside the facility and in the direction of the atmosphere!"

When it comes to the all-metal-sealed angle valves, the VAT designers took a slightly different approach: Instead of a double housing, the wall thickness of the valve was enormously increased. In these valves, another special feature also stands out: While in conventional VAT valves, the bellows feedthrough is realized by a single hydroformed bellows, it was designed in a double version for the ITER angle valves. "This way, if one of the bellows feedthroughs fails, there is still a backup!" says Phil Schneider, explaining this decision.

A very special ITER valve…

Although the ITER catalog covers an amazingly wide range of valves, special developments are of course always necessary. Phil Schneider fondly remembers one particularly impressive example: "In order to isolate the volumes of the tokamak reactor and the neutral beam system from each other, and to enable independent ventilation, we developed a truly special all-metal pendulum valve together with ITER – the Absolute Valve. It takes advantage of the patented metal-sealing VATRING technology and, with an opening diameter of 1.6 m, is the largest pendulum valve ever developed using this technology!"

Of course, if such tailor-made solutions are too specialized or are only needed at certain times, it is not expedient to include them in the official ITER catalog. "Rather, they either go directly to ITER or to the appropriate purchasing companies," comments Phil Schneider.

Due to the enormously high requirements that ITER has with regard to the quality of the components used, the ITER catalog was an excellent opportunity for VAT to once again demonstrate its outstanding capabilities around valve development and distribution. "We are delighted that ITER has entrusted us with this challenging task," says Phil Schneider. "VAT has a lot of experience with customer-specific valve portfolios, for example with customers in the semiconductor industry or with systems for the series production of mass spectrometers and microscopes, but the dimension of the ITER catalog was also something special for us."

Full customer satisfaction

So it's even nicer that the concept of the customized VAT valve portfolio is very well received by ITER and its suppliers! Phil Schneider's conclusion: "The excellent results we were able to achieve together with ITER are a great example of the high degree of differentiation that can be achieved with such portfolios. And they impressively demonstrate how the technical complexity of plants can be effectively reduced without having to compromise on quality."

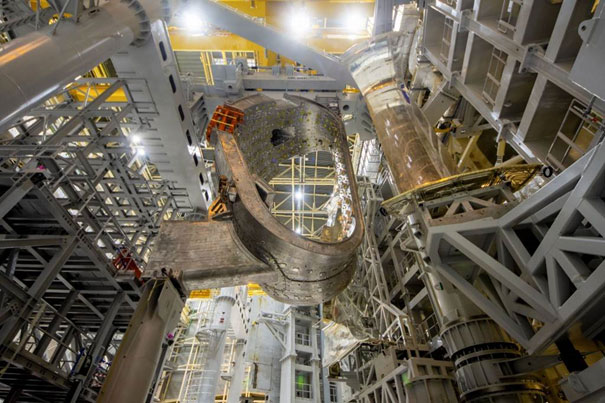

Incredible dimensions: one sector of the vacuum vessel is installed in the ITER nuclear fusion facility. The VAT valve portfolio, specifically tailored for ITER, supports the uniform, highly reliable design of the vacuum systems.

Source: ITER