15.1

1 × 10-8 mbar to 1 bar (abs)

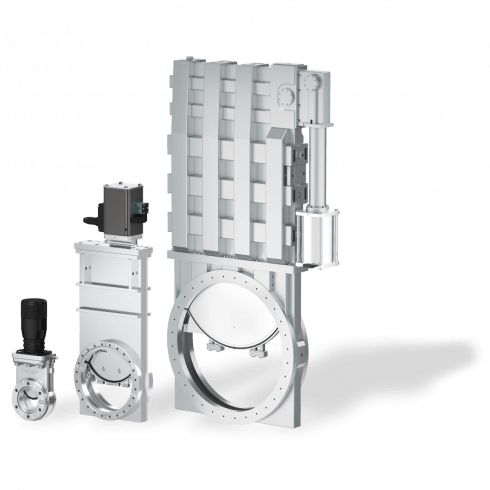

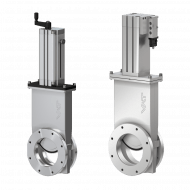

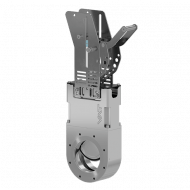

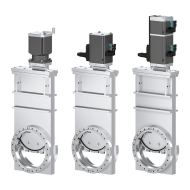

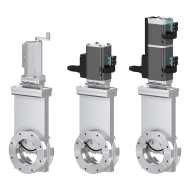

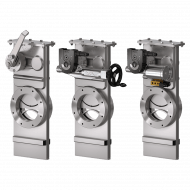

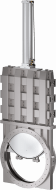

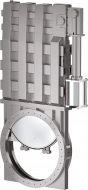

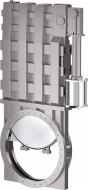

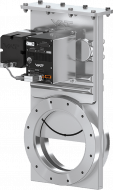

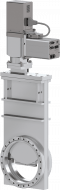

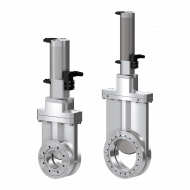

HV Isolation Gate Valve

Exceptionally Low Shock and Particle Count

FAQ Vacuum Gate Valves

What is a vacuum gate valve?

A vacuum gate valve is a type of mechanical device used in vacuum systems to control the flow of gases in and out of a vacuum chamber. It consists of a sliding gate or plate that can be moved to either block or allow passage through a vacuum valve body, effectively sealing off the chamber from the external environment. It thus belongs to the class of vacuum isolation valves. However, there are also variants that can be used to control the gas flow.

What are the key features of vacuum gate valves?

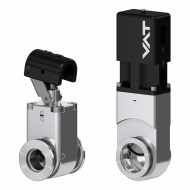

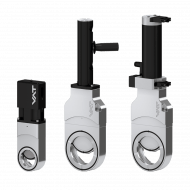

Vacuum gate valves are designed with a few distinct characteristics. They have a robust construction, often using materials like stainless steel or aluminum for their resistance to vacuum conditions. The sealing mechanism ensures a high level of vacuum integrity when closed, preventing leaks and maintaining the vacuum pressure within the chamber. These vacuum valves can be actuated manually, pneumatically, or electronically, allowing for versatile control based on the specific application.

How do vacuum gate valves operate?

Vacuum gate valves operate by using a sliding gate mechanism to control the passage of gases. When the vacuum valve is open, the gate is moved out of the flow path, allowing gases to pass through with a high conductance. Closing the vacuum valve involves moving the gate across the flow path to create a seal. This sealing mechanism is crucial to maintaining the vacuum conditions within the chamber. To avoid particle generation in particle sensitive applications the sliding gate mechanism is designed to avoid friction at the valve housing.

What are the applications of vacuum gate valves?

Vacuum gate valves find applications in various industries, including semiconductor manufacturing, research and development, analytical instrumentation, and vacuum coating. They are essential for isolating different vacuum chambers, controlling gas flows during processes, and facilitating maintenance or repairs without compromising the vacuum environment.

What considerations are important when using vacuum gate valves?

When using vacuum gate valves, factors like compatibility with process gases, operating pressure range, cycle speed, and maintenance requirements should be considered. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential for optimal performance and longevity of these valves. Additionally, selecting the appropriate size and type of vacuum gate valve for the specific vacuum system and process is crucial to ensure efficient operation and reliable vacuum integrity.