The origin is an idea, a vision or an existing project. We define a module as an assembly of vacuum valves and other vacuum components in a customized housing. Each module we create is tailored to specific requirements. Depending on the requirements and lot size, we also develop a dedicated maintenance and spare parts concept in addition to the module. In this way, we ensure the full functionality of the modules over the defined life cycle.

The Advantage

As a complete assembly from a single source, it is ensured that all components interact in an optimal manner. Performance parameters can be defined in a simplified manner for the overall system rather than for each component individually.

Each VAT module simplifies and speeds up the assembly of a complete system, as it is supplied as a ready-to-assemble unit. With only one part number, it also reduces the complexity of the supply chain, reduces the parts list and thus the logistics effort required to keep the parts ready. This simplifies the procurement process for module series and enables ship-to-line.

Advantages that allow significant cost savings with high production quality.

High Purity as Standard

VAT's proven expertise in vacuum component solutions for ultra-clean vacuum applications means that all production steps, from machining to assembly, testing and packaging, are organized under high to very high purity standards. ISO class 6 is the standard here, although higher requirements can also be met in sub-steps. All manufacturing processes including all cleaning processes are documented and strictly monitored. VAT is able to monitor the purity of individual components in production through in-situ particle monitoring.

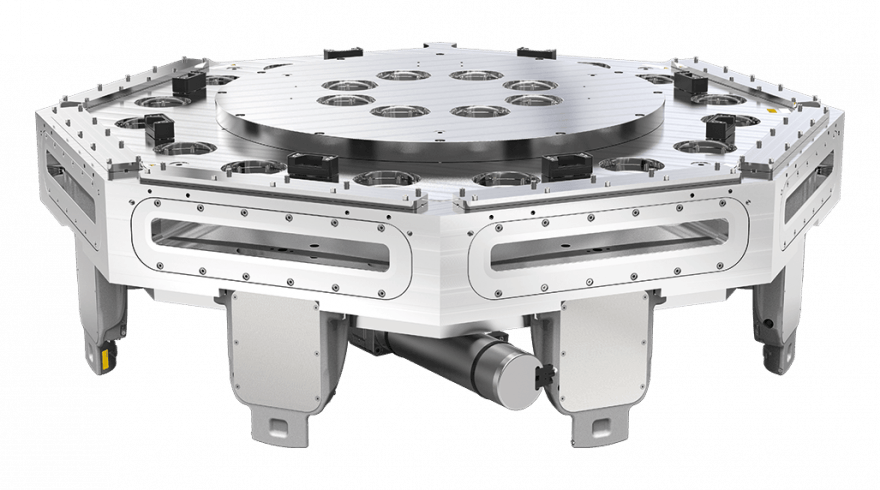

Higher Integration - More Compact Design

With design and manufacturing from a single source, VAT modules offer the advantage of allowing a higher degree of integration than modules conventionally manufactured from individual components. For example, valve functions can be integrated directly into the module housing instead of being flanged on. This usually results in much more compact dimensions with the same or even better performance parameters. Furthermore, a high degree of integration reduces the number of parts as well as material usage.

The more compact design also allows optimization of the internal volume and the surface in contact with the media. Unnecessary interfaces are eliminated and the overall length of the seals is shortened, reducing permeation. This results in lower process gas volumes, which in turn leads to shorter times for evacuation and venting. Overall, this can lead to higher production throughput, at lower base pressure, and thus to greater cost efficiency, for example, through the use of smaller vacuum pumps.

Benefiting from Experience

VAT modules are used in a wide variety of vacuum processes worldwide. The experience gained from an installed base of more than 10,000 modules benefits every project we implement for our customers. Contact us to learn more about VAT modules.

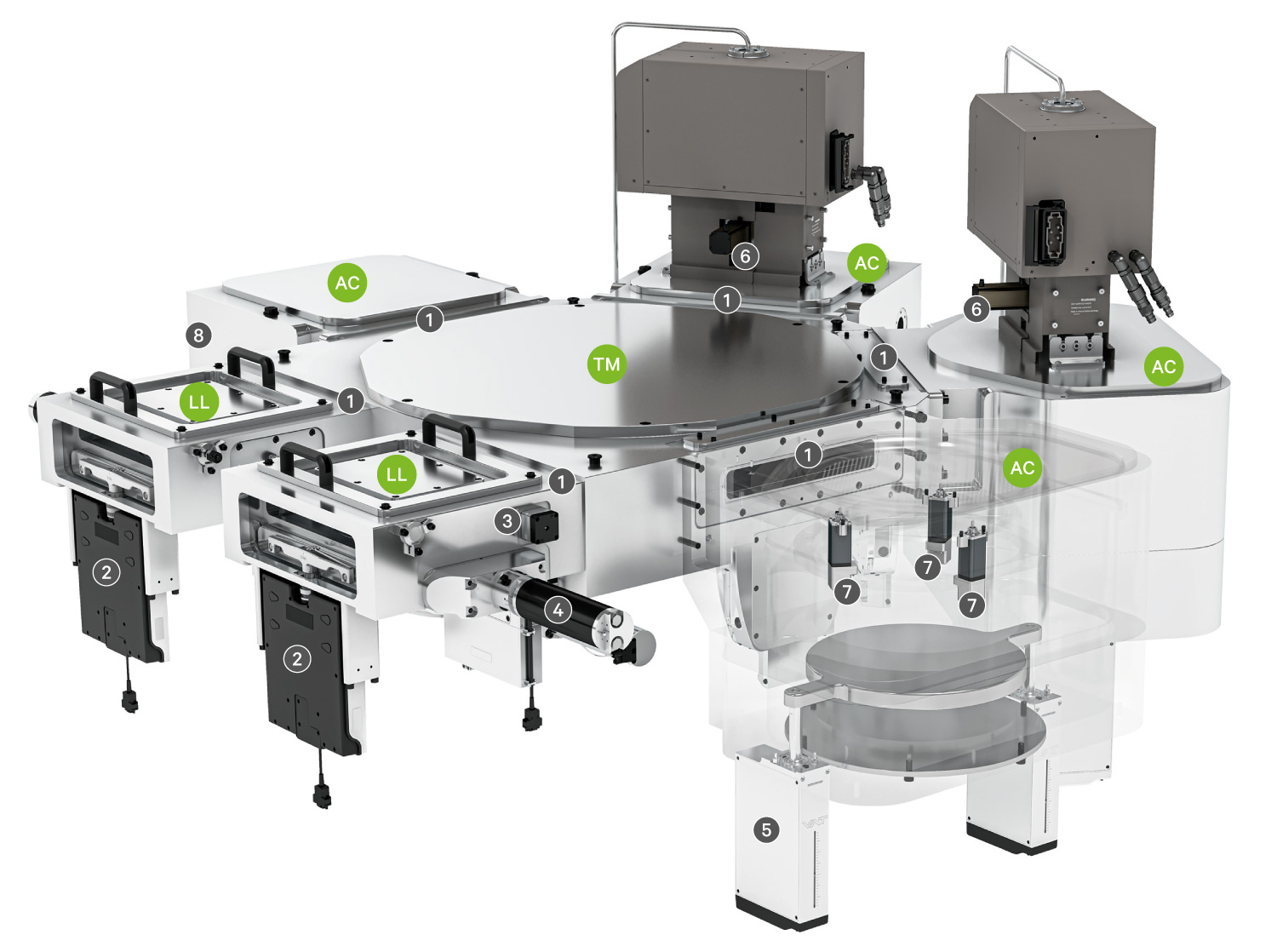

Components

VAT Load-Lock Modules (LL)

VAT Transfer Modules (TM)

VAT Adjacent Components (AC) e.g.:

VAT Wafer Lift Systems (7)

VAT Edge Welded Bellows