Solar Thin Film Deposition

Solar panel manufacturers use a variety of coating processes (CVD, ALD, MBE, PVD, etc.) to produce the ultra-thin films that make up the performance o...

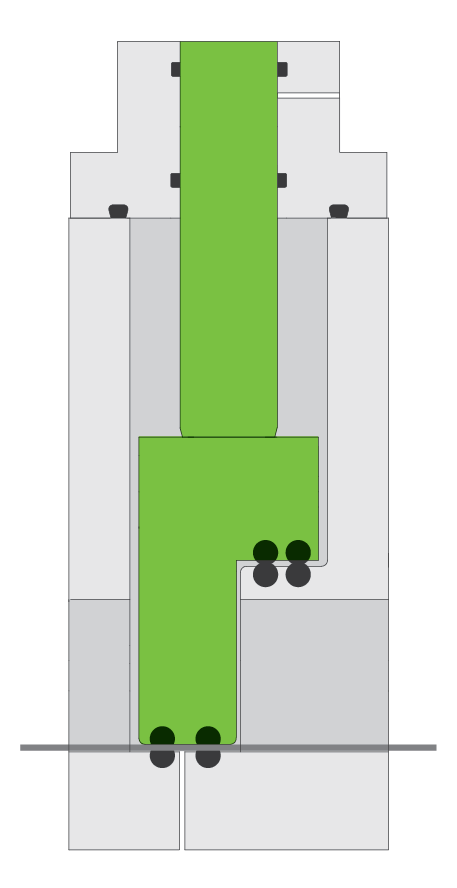

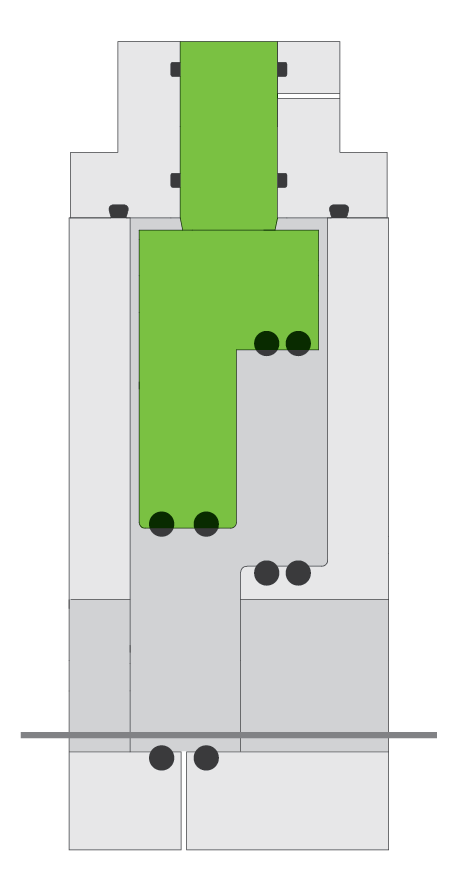

Read moreThe 02.7 Roll-to-Roll Transfer Valve MONOVAT has been developed to meet the special requirements of continues web/foil coating processes. To ensure reliable sealing of the process chamber in line with protecting the web/foil band in continues coating processes the 02.7 is using a sophisticated roll-to-roll sealing system. The sealing system is based on VAT’s proven MONOVAT sealing technology. With the double sealing roll-to-roll design the sealing pressure is perfectly balanced between effective sealing and not damaging the web/foils. An intermediate pumping stage between both seals adds to the sealing performance.

Designed for high cycle production systems the 02.7 combines an outstanding fast motion time (≤ 1.5 s) with resistance against process-related deposits that would limit standard valve performance.

The special MONOVAT sealing technology used by the 02.7 allows a shock-free opening and closing movement of the gate minimizing particle activation and reducing seal wear. Furthermore, the for a double sealing system very compact design of the sealing mechanism also makes the whole valve very compact providing small mounting dimensions.

Operating already in hundredths web/foil production systems around the world under various process conditions, the 02.7 series has proven its outstanding performance in all aspects.

The 02.7 Roll-to-Roll Transfer Valve MONOVAT is tailored to exact customer specification like all VAT transfer valve solutions. Elements of these customization are a solenoid valve for impulse actuation, special surface treatments like hard anodized or nickel-plated aluminum, bellows sealed feedthrough and more.

Features:

Benefits:

| Sizes | 50 × 300 mm (1.97" × 11.81") to 50 × 1250 mm (1.97" × 49.21") |

||

|---|---|---|---|

| Actuator | Pneumatic | Double acting with position indicator | |

| Body Material | Aluminum or Stainless Steel | ||

| Feedthrough | Shaft Feedthrough with intermediate pumping | ||

| Leak Rate | Valve Body | < 1 × 10-5 mbar ls-1 | |

| Valve Seat | < 1 × 10-5 mbar ls-1 | ||

| §Differential Pressure | On the Gate | ≤ 1 bar | |

| At Opening | ≤ 5 mbar | ||

| Cycles until first Service | 10 000 | ||

| Closing or opening time | ≤ 1.5 s (with 50 mm opening height) | ||

| Temperature | Aluminium Valve Body/Gate | ≤ 120 °C | |

| Stainless Steel Valve Body/Gate | ≤ 150 °C | ||

| Actuator, Position Indicator | ≤ 80 °C | ||

| Temperature Difference Body/Gate | ≤ 25 °C | ||

| Material | Aluminium Valve Body/Gate | EN AW-5083 (3.3547) | |

| Stainless Steel Valve Body/Gate | AISI 304 (1.4301) | ||

| Actuator Shafts | AISI 304 (1.4301) | ||

| Seal | Gate, Flanges, Feedtrough | FKM (Viton®) | |

| Mounting Position | Actuator Up or Down | ||

| Position Indicator | Voltage | 10 – 30 V DC PNP (NPN optional) | |

| Tensile force of the foil on the gate | max. 0.5 N per mm (e.g. width of foil 300 mm, max tensile force 150 N) | ||